Four Features Of Panasonic Tough Contact Connector Construction

Panasonic’s industry-leading Tough Contact construction offers the opportunity to design very durable Connectors for extremely tough and rugged applications, even applications that need to satisfy extreme environmental conditions. Able to withstand physical impact, Tough Contact Connectors are resistant to dust, dirt, and solder flux, and are resistant against corrosive gases.

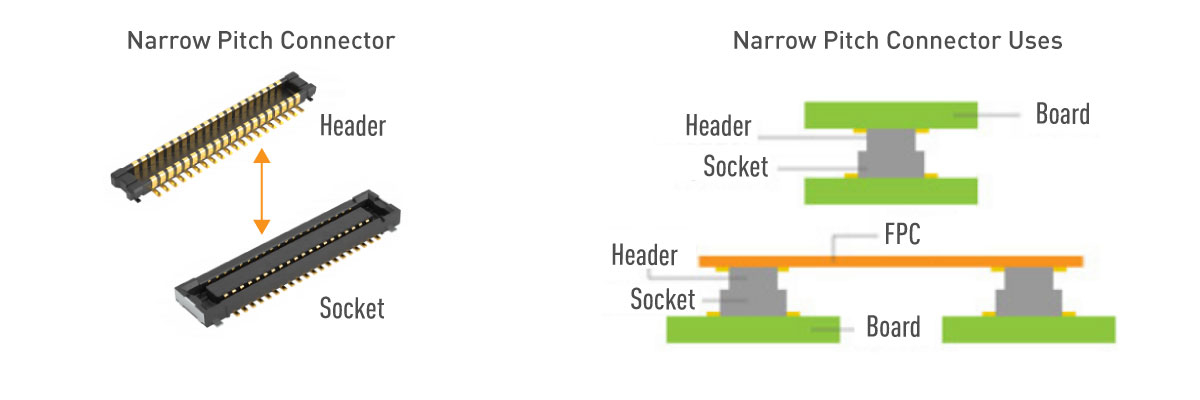

Narrow Pitch Connector Structure

Engineered and manufactured for durability and long lifetime, Panasonic's Tough Contact Connectors increase tolerance to twisting and dropping, resistance to dust and foreign particles and resistance to corrosive cases

Panasonic Narrow Pitch Connectors are constructed for high-reliability use in various environments when board-to-board and board-to-FPC signal transfer is needed, particularly when space is limited. Four key features make up the “Tough Contact” formula which makes Panasonic Connectors used in handheld devices extremely reliable in the harshest environments

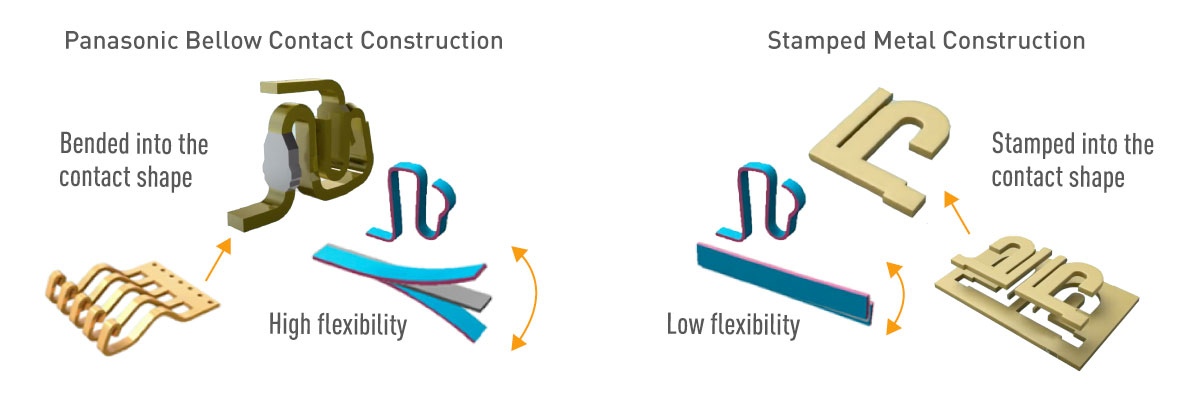

1.Bellows Contact Shape

Through a special metal bending process, Panasonic achieves high spring characteristics of the contacts which provide both smooth insertion and proper removal force. Clear tactile feedback also helps alert the user to prevent improper mating. Most importantly, drop impacts can be absorbed without electrical disconnection, especially for handheld devices. Bending the metal also allows for a much smoother surface for higher contact reliability. In contrast, many other manufacturers stamp out the contacts from a metal sheet which has much lower flexibility and may result in a solder crack when dispersing stress from impacts. Also, the stamping process may create a fractured surface which poses a risk of flaking as contacts are worn down.

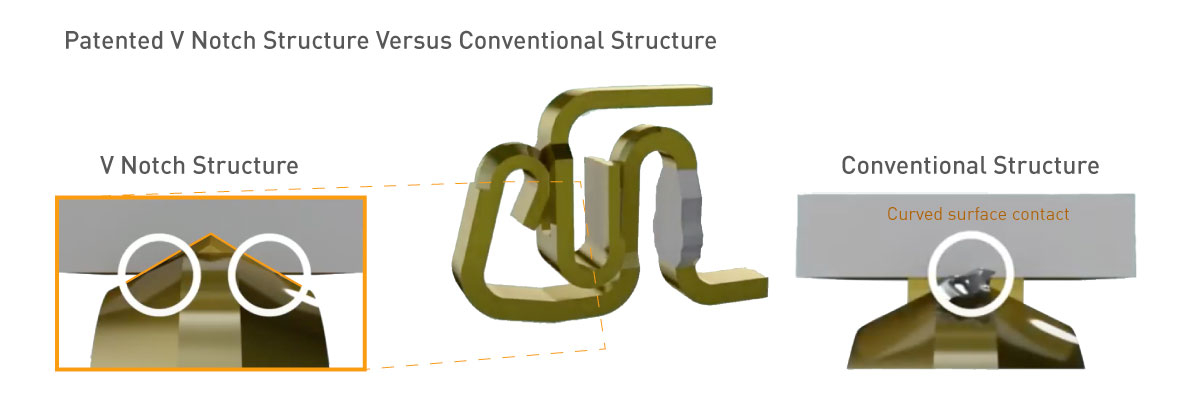

2. V Notch Interface

Panasonic has a patented V Notch Construction which increases the contact pressure per unit area by using two separate surface-to-edge contact points as the interface between the socket and header terminals. Compared to other types of contacts, this design allows for an improved ability to remove and prevent dirt, dust, dispersed flux, or other foreign particles that may block the connection from falling through the groove between the two points of contact.

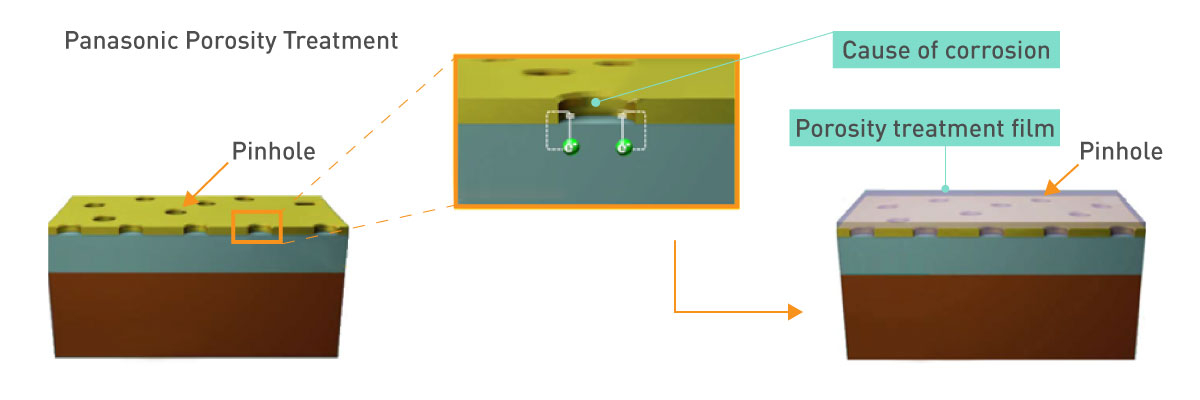

3. Porosity Treatment

All Panasonic connectors use a Porosity Treatment on the gold surface of the contacts to ensure long-term stable contact reliability. Although gold is primarily used for the contact surface to increase corrosion resistance, the layer of gold is very thin (around 01.-0.2µm). This may lead to the generation of pinholes susceptible to galvanic corrosion exposing the Nickel Plating underneath the thin gold surface. Using an electrically conductive film to coat the gold surface, these pinholes can be sealed to maintain high contact reliability equal to thick gold plating even in adverse conditions such as the presence of corrosive gases. Furthermore, the lubricating constituents of this film contributes to higher insertion and removal durability.

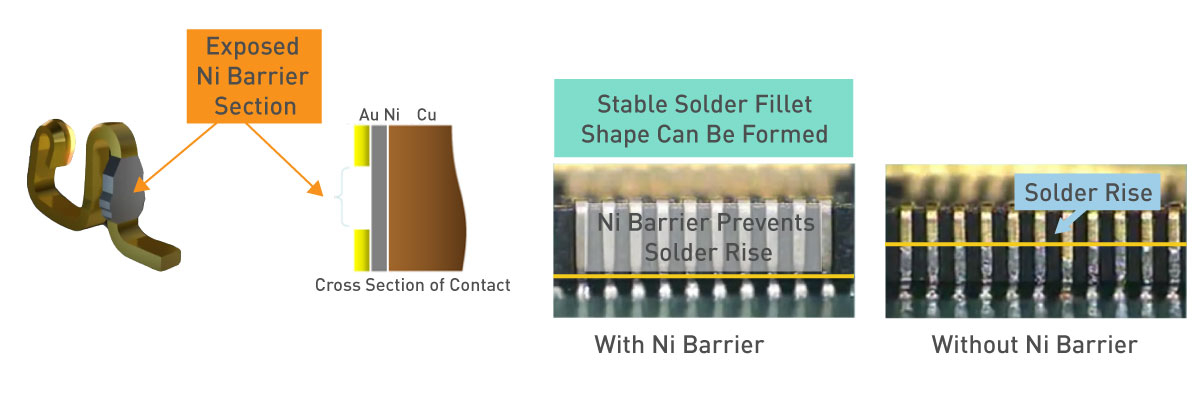

4. Exposed Nickel Barrier

Due to the compact size and low profile of narrow pitch connectors, special attention must be considered to prevent “solder rise” from occurring. Panasonic uses an exposed Nickel barrier which prevents solder from rising the terminal and allows for a reliable solder fillet mold to form.