EV Inverters

Panasonic Industry is proud to present its cutting-edge EV Inverter solutions, designed to meet the demanding needs of the electric vehicle market. Our comprehensive range of products includes high-performance automotive relays that ensure reliable power management, anti-surge resistors that protect circuits from voltage spikes, and thin film resistors that deliver exceptional precision. Additionally, our Wide Terminal Thick Film Resistors provide robust performance for high-current applications, while Thermistors offer precise temperature sensing for optimal operation. Our Capacitors and Inductors are engineered with advanced materials and technology to enhance energy efficiency and stability, making them ideal for EV inverter systems. Together, these components form a reliable and efficient solution that empowers the next generation of electric vehicles.

Contact Your Dedicated Resource for Any Questions

Capacitors Solutions Custom Made for xEV

Stricter environmental regulations aimed at reducing CO2 emissions have significantly boosted the eco-friendly vehicle (xEV) market, prompting car manufacturers to expand their xEV offerings by replacing gas-powered vehicles. This shift has led to a heightened demand for small, high-performance DC-link capacitors used in driving inverters, which Panasonic has successfully addressed through its advanced vapor deposition technology and safe fuse structure design.

xEV Film Capacitor Product Features

1. High Safety

This capacitor is equipped with a security mechanism fuse function that ensures the product's safety by utilizing an open failure mode. The original security mechanism features high-precision pattern deposition, where fuses are optimally arranged on a deposited film. This design directs any potential failure to an open failure mode, preventing ignition or smoking accidents that could result from a short failure mode. As a result, this contributes to the enhanced safety of vehicles.

2. Miniaturization

To achieve the miniaturization of the capacitor, Panasonic adopted a highly voltage-resistant polypropylene (PP) film with reduced thickness. This innovation helps to decrease the overall thickness of the capacitor. Collaborating with film manufacturers, Panasonic developed this advanced film, successfully minimizing the size and weight of the inverter. As a result, this miniaturization has paved the way for more compact and lightweight inverter designs.

3. High Power Output

Panasonic's innovative vapor deposition technology significantly reduces self-heating in capacitors by lowering their equivalent series resistance (ESR). This improvement enables the capacitors to handle high power output from inverters more effectively. Using patented high current pattern deposition and a heavy edge construction method, Panasonic's original technologies further mitigate self-heating, allowing capacitors to manage larger allowable currents. As a result, this contributes to an overall increase in power output from the inverter.

Fuse Function Technology of Panasonic Film Capacitors

Polymer Hybrid Aluminum Electrolytic Capacitors

Panasonic's Hybrid Capacitors offer a unique blend of advantages from both Aluminum Electrolytic and Specialty Polymer Capacitors. Here are some key features and benefits:

High Endurance: These capacitors are designed to withstand prolonged use, ensuring longevity in various applications.

Low ESR (Equivalent Series Resistance): This characteristic allows for better performance in high-frequency applications, reducing energy losses and improving efficiency.

High Ripple Current Tolerance: They can handle significant ripple currents, making them suitable for power supply circuits and other demanding environments.

Inrush Current Handling: Hybrid Capacitors can manage sudden surges in current, which is crucial for applications with high startup demands.

Elevated Temperature Performance: They maintain stable performance even at higher temperatures, making them reliable in challenging conditions.

Compact Size: Their smaller footprint allows for more efficient use of board space, which is especially beneficial in compact electronic designs.

Vibration-Proof Options: Some models are designed to withstand vibrations, enhancing reliability in applications where movement is a factor.

Overall, Panasonic's Hybrid Capacitors are designed to withstand extreme conditions, making them perfect for automotive, server, base station, and industrial PC applications that require reliability, efficiency, and space-saving solutions.

Automotive Relays for EV Inverters

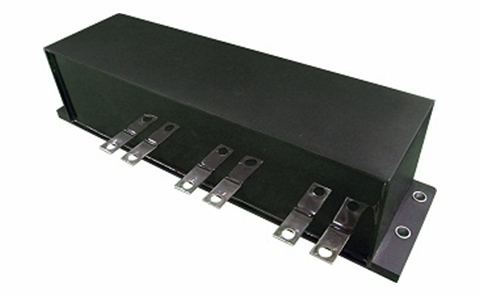

TL Series Automotive Relays 2 Form A (40A)

Panasonic's TL Series Automotive Relays 2 Form A are designed for smart junction boxes, providing a robust solution for high load applications. These relays feature a miniature design that allows them to switch larger capacity loads effectively, utilizing a double-make 1 Form U (or 2 Form A) contact arrangement. This innovative structure enables impressive switching capabilities of up to 40A.

Choose Panasonic's TL Series for a reliable and efficient solution that meets the needs of modern automotive systems.

TT Series Automotive Relays High Capacity PC Board (60A)

Panasonic's TT Series high-capacity Automotive Relays are designed for smart junction boxes, offering robust performance with a remarkable capacity of 60A. Its protective construction ensures reliability in demanding automotive applications.

Choose this high-capacity PC board relay for reliable performance in your automotive applications.

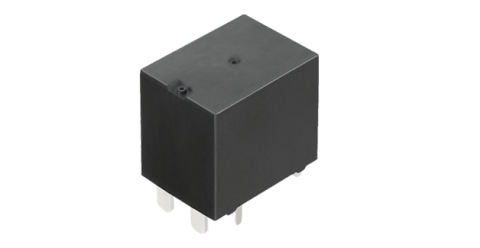

PhotoMOS®

Panasonic PhotoMOS® Semiconductor Relays are MOSFET-enabled Solid State Relays featuring low off-state leakage current and stable on-resistance over the component lifetime. Low CxR values, high optical isolation between input and output, and DC and AC / DC load ratings. MOSFET drivers are available in SSOP, SOP 4-pin, and DIP 6-pin.

AEC-Q200 Compliant Resistors

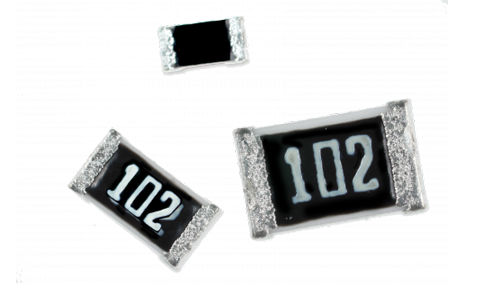

High Precision Thin-Film Chip Resistors

It offers exceptional reliability, accuracy (up to 10ppm, 0.05%), and low noise, which is suitable for demanding applications in automotive, appliance, and industrial markets, with case sizes down to 0201 and AEC-Q200 compliant.

Anti-Surge Thick Film Chip Resistors

The ERJ-P Series High Power Resistors offer a smaller size, greater power, and more ESD tolerance than standard Thick Film Chip Resistors. Complete with metal glaze, thick film resistive elements, and three layers of electrodes.

Shunts: Wide Terminal Thick Film Resistors

Featuring a diverse range of case sizes ranging from 0402 to 2512 in conventional terminal and 0612 to 1020 for wide terminal types, offering power ratings up to 2W and low ohmic ratings from 5mΩ to 10Ω, providing a cost-effective solution with high reliability.

NTC SMD Thermistors

NTC SMD Thermistors are multilayer devices that inversely change resistance values according to temperature. They detect, measure, or compensate for temperature. For example, they can be used to monitor battery charging and sense when the battery is fully charged. Panasonic offers a wide selection of Surface-Mount NTC Thermistors that are small, lightweight, and suitable for high-density placement.

Power Inductors for Automotive Applications

Panasonic Power Choke Coils are indeed a robust choice for surface mount power inductors, offering several key advantages:

High Heat Resistance: Designed to operate effectively in high-temperature environments, these coils maintain performance and reliability even under thermal stress.

Excellent DC Bias Characteristics: They exhibit minimal changes in inductance with varying DC bias, ensuring stable performance in applications with fluctuating currents.

Hi-BS Ferrous Alloy Magnetic Material: This material enhances magnetic performance, allowing for efficient energy transfer and improved overall inductance.

Reliability at High Temperatures: These coils are engineered to withstand elevated temperatures, making them suitable for demanding applications.

High Tolerance for Vibration: Their design accommodates vibrations, ensuring consistent performance in environments subject to mechanical stress.

Low Audible Noise: With a focus on reducing noise, these coils operate quietly, which is beneficial in noise-sensitive applications.

Low DCR (Direct Current Resistance): This feature contributes to higher efficiency, minimizing energy loss during operation.

Eddy Current Loss Reduction: The design minimizes eddy current losses, further enhancing the efficiency of the inductors.

Overall, Panasonic Power Choke Coils are ideal for applications requiring high reliability, efficiency, and performance in challenging environments, such as power supplies, automotive electronics, and industrial equipment.

Panasonic Automotive Solutions for Electrified Drivetrain

Explore Panasonic's innovative drivetrain solutions, tailored for electric vehicles. Our technology powers key applications such as Battery Management Systems, Inverters, DC-DC Converters, and Onboard Chargers, enhancing vehicle performance, efficiency, and eco-friendliness.