New Prepreg for Millimeter Wave Antennas: R-5410

- Electronic Materials

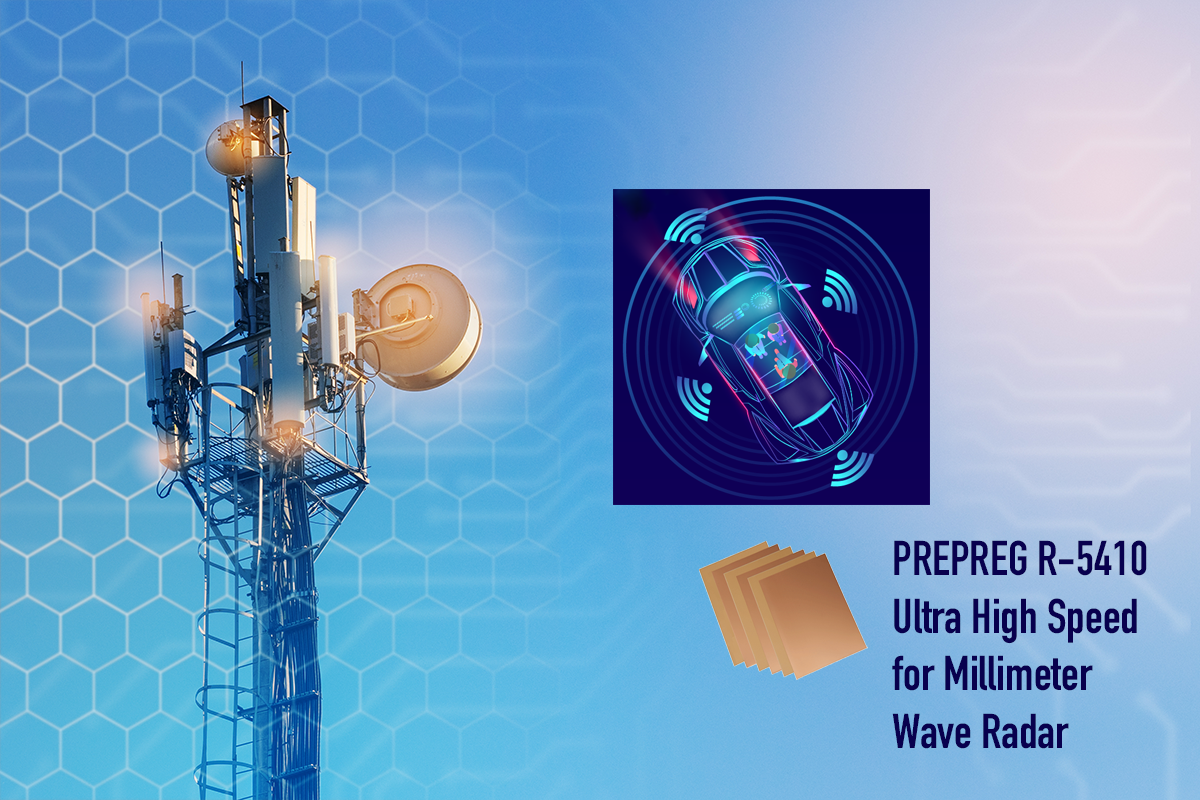

Now available is Panasonic’s new halogen-free, ultra-low transmission loss multi-layer Circuit Board Prepreg. This new Prepreg enables multi-layer millimeter wave antenna construction using industry-standard manufacturing processes and equipment.

Applications include millimeter-wave antenna Circuit Boards, automotive millimeter-wave radar, wireless communication base stations and high-transmission speed multi-layer Circuit Boards.

Key benefits include lower transmission loss, ease of construction, and reduced manufacturing costs.

Halogen-free Ultra-low Transmission Loss Multi-Layer Circuit Board Prepreg for mmWave Antenna R-5410

mmWave radar technology uses short-wavelength electromagnetic waves to send and receive signals from objects in their path. By processing the reflected signal, these systems can determine range, velocity and angle of the objects and hence are a key technology for driving environment recognition platforms that enable advanced driver-assistance systems (ADAS.) Wireless communication base stations also use millimeter-wave bandwidths and the rapid adoption to support 5G deployment has increased the performance requirements for the high-frequency Circuit Boards used in these systems.

The newly developed R-5410 Halogen-free Ultra-low Transmission Loss Multi-Layer Circuit Board Material is a Prepreg made from a unique non-fluoropolymer thermosetting resin system. Historically the fluoropolymer Circuit Materials can be challenging to laminate into multilayer constructions, but this new Prepreg enables multi-layer antenna construction using industry-standard manufacturing processes and equipment.

Applications

- Millimeter-wave antenna circuit boards

- Automotive millimeter-wave radar

- Wireless communication base stations

- High transmission speed multi-layer circuit boards

Lower Transmission Loss Leads To Increased Efficiency Of Millimeter-Wave Signals

Leveraging Panasonic's proprietary thermosetting resin design technology, this new material exhibits excellent dielectric properties and good adhesion strength with low-profile copper foils. This combination of properties delivers the industry's lowest level transmission loss for thermosetting resin circuit boards thus reducing signal losses and improving the efficiency of millimeter-wave band communications.

Improves Antenna Design Flexibility Because Of Ease Of Construction

This Prepreg is made from a proprietary low-loss thermosetting resin. R-5410 enables the lamination construction of multi-layer boards. The new material enables the design and production of compact and high-density modules integrated with antennas, thus improving the efficiency of antenna performance. Complementary materials like product number R-5515 Halogen-free Ultra-low transmission loss laminate are core materials in this product family and are also commercially available.

Reduces Circuit Board Manufacturing Costs

Since this is a thermosetting resin material, it can be processed using standard circuit board manufacturing equipment. It requires no special chemical solutions or processes. This feature enables more complex multi-layer circuit layouts, while simultaneously reducing material and processing costs.