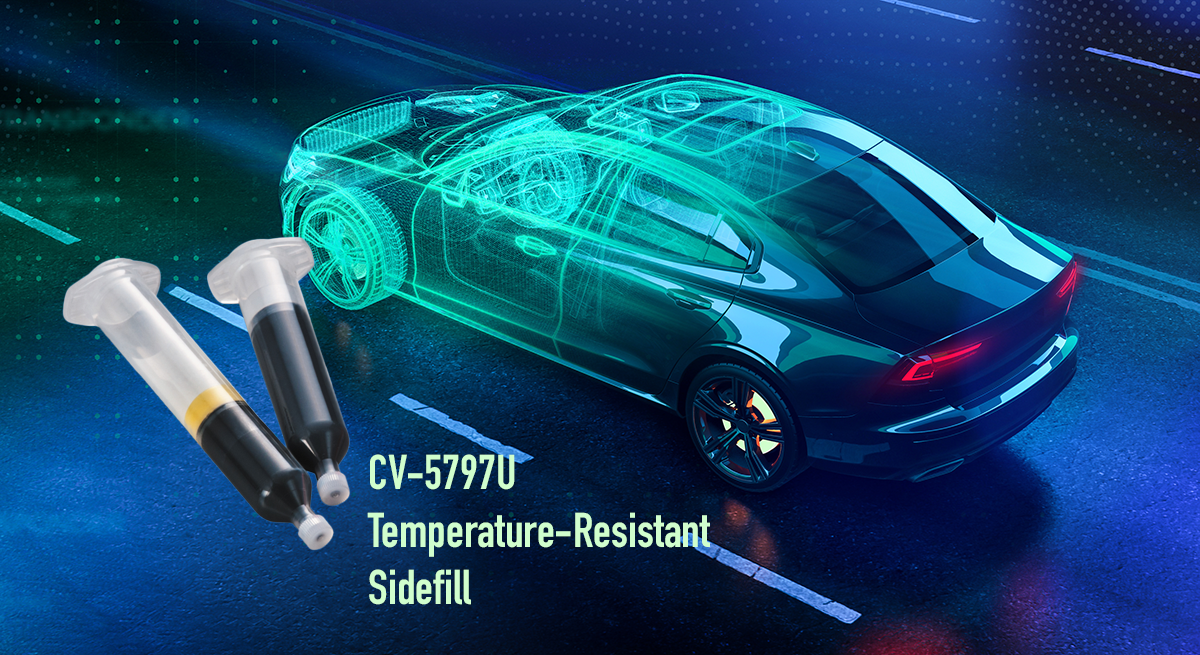

New Temperature-Resistant Sidefill for Surface Mount Assembly Reinforcement

- Electronic Materials

Ideal for automotive electronics which need to function under extreme conditions, this Sidefill contributes to improved reliability of surface mount semiconductor packages and enables easier handling during manufacture due to long pot life.

Applications include automotive camera modules, automotive communication radar, automotive electronic control units (ECUs), next-generation cockpits, and headlights.

CV5797U Improves The Reliability And Productivity Of Automotive Electronic Assemblies

It’s imperative that automotive electronics operate reliably under punishing conditions: shock, vibration and temperature extremes. As automotive sensing, control and communications are becoming increasingly sophisticated and powerful, the electronics that enable them are becoming more complicated. Semiconductor packages are larger, interconnects smaller, and system designers pack more components on every bit of available circuit board real estate. This increased component density means those semiconductor packages are exposed to greater thermal stresses over their operational lifetime which fatigues the interconnect joints and can lead to solder cracking and ultimately device failure.

To address this problem, Panasonic is developing a portfolio of surface mount reinforcement materials, including Temperature-Resistant Sidefill, CV5797U. Based on Panasonic’s polymer formulation capabilities and flow control technologies, the new Sidefill prevents solder cracking by reinforcing the periphery of semiconductor packages where thermally induced strains are the greatest. With a pot life three times longer than conventional Sidefill (72 hours under ambient conditions), CV5797U reduces the material handling challenges normally associated with reactive liquid adehsives, leading to higher productivity in the electronic assembly process.

Applications

- Automotive Camera Modules

- Automotive Communication Modules (Millimeter-Wave Radar)

- Automotive Electronic Control Units (ECUs)

- Next-Generation Cockpits

- Headlights

Improves Assembly-Level Reliability By Preventing Solder Joint Failure

Given the wide range of operating conditions for electronics in automobiles, an effective approach for improving assembly level reliability is to reinforce the mounted components with a polymeric component highly resistant to heat and exhibits minimal thermal expansion and contraction over a wide range of temperatures. CV5797U strikes the right balance with the high glass transition temperature (Tg) and low coefficient of thermal expansion (CTE) needed for these applications. Reinforcing components with this sidefill helps address the inherent CTE mismatch between an automotive motherboard and a mounted semiconductor package, thus reducing the stress on the solder joints.

Improved Handling Performance Leads To Higher Productivity During Manufacturing

Due to the long pot life (72 hours at ambient conditions) CV5797U is easier to manage during the manufacturing process, contributing to higher productivity in the mounting process. This Sidefill also reduces reinforcement process time by 90 percent compared to conventional underfill and can be applied at high speed using a jet dispenser. All this contributes to a reduction in total assembly process cycle time.

Improved Reliability Of Large Surface Mount Packages

When applied to the periphery of a package, Sidefill creates a reinforcing fillet around semiconductor packages, including ones larger than 25 mm × 25 mm - which is extremely difficult to achieve with underfill. CV5797U Sidefill is indispensable for manufacturing automotive-grade electronic assemblies.