Panasonic's PIR Motion Sensors

Developed from the ground up over 22 years, production of PaPIRs has exceeded 100 million units. Here we go behind the scenes of the product, which will be key to a data-driven society.

PaPIRs: Panasonic’s Passive Infrared or Pyroelectric (PIR) Motion Sensors —100+ Million Units Produced; Used by More Than 500 Companies Worldwide

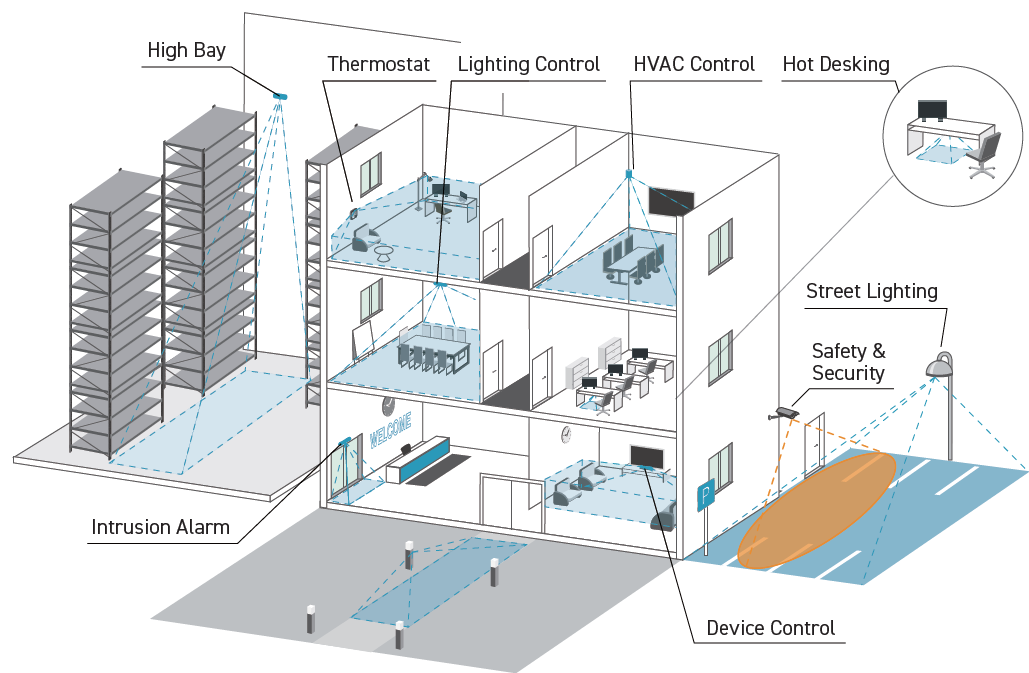

In May 2022, the total production of PaPIRs—Panasonic's PIR Motion Sensors—exceeded 100 million units. PaPIRs are used widely in lighting controls, security cameras/alarms, home appliances, and many other applications. More recently, they have been used in unique ways suited to the pandemic, such as turning on displays that encourage the use of disinfectant when people walk past and turning on large displays only when motion is detected. Furthermore, with excellent compatibility with IoT technologies, the sensors can also be used to communicate the availability of meeting rooms and restaurants, as well as record in-store movement to collect large amounts of data. While the mechanisms of PIR Motion sensors themselves are relatively simple, their applications can grow greatly depending on the idea.

With an extensive line-up, PaPIRs are helping to quickly actualize customers’ ideas. The sensors are used by more than 500 companies worldwide, and their performance is acclaimed throughout the world. In this article, we interview one of PaPIRs’ developers to find out more about the product’s strengths.

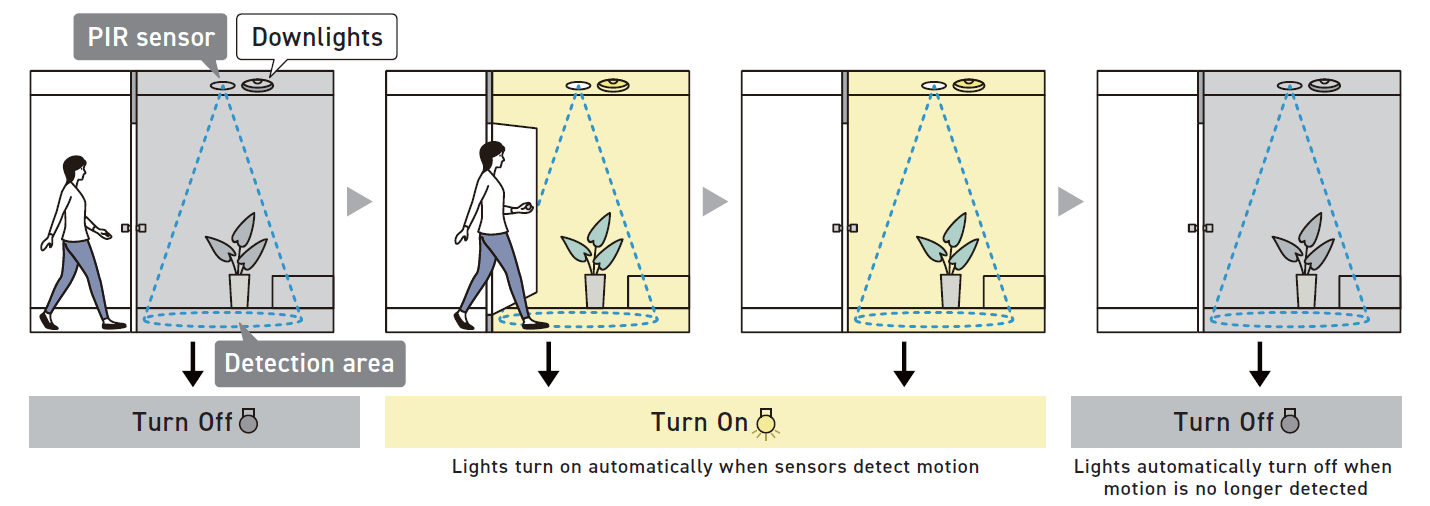

PIR Motion Sensors are currently garnering major attention, but perhaps only specialists will know exactly what they are. Motion sensors, which are used to automatically turn on lights in toilets, for example, might be more familiar. Motion sensors react to movement and turn lights on and off. PIR Motion Sensors are frequently used for such applications.

Infrared waves are a type of electromagnetic wave. In fact, although invisible to the naked eye, people and animals constantly radiate infrared rays. PIR Motion Sensors react by detecting changes in the energy of the infrared rays. As can be seen in the fact that some motion sensor-compatible lighting fixtures run on dry-cell batteries, motion sensors consume little energy. Hence, in an era in which electricity shortages are a severe concern, PIR Motion Sensors—which can automatically turn lights off—are garnering attention for their ability to save energy.

Uses for PIR Motion Sensors continue to become more diverse. In addition to lighting control, they are used to control home appliances, detect room occupants, ensure security, and detect intruders.

Production of PaPIRs began in 1998 at the Tsu Factory in Mie Prefecture, which is mainly responsible for producing wiring devices. Automatic motion sensor switches were first introduced into our product line-up in 1988. At the time, we were commercializing these products using devices purchased from other companies. In-house, though, we already had several products that could be controlled by motion sensors, such as lighting fixtures and wiring devices. Believing that motion sensors would become key devices in the future, a president-led project was launched in 1995. As we were fixture manufacturers, we had no experience in producing devices from the ground up, and so although we came across numerous issues in development, with the collective wisdom of others in the company, we successfully achieved mass production in three years.

What type of product did you endeavour to create to compete against preceding manufacturers?

First, we wanted to build the sensors into our other products, and so we paid special

attention to making the components as small as possible to ensure they wouldn’t

impact the design of these other products. We thus purposely set ourselves the

difficult challenge of manufacturing a sensor with an integrated lens. Furthermore,

preparing a sensor and lens separately and then putting them together would have

been a time-consuming process as those in charge of the development of each part

would have to carefully examine their respective specifications. In integrating the

sensor and lens, we also thought we could reduce manpower in development.

What type of product did you endeavour to create to compete against preceding manufacturers?

First, we wanted to build the sensors into our other products, and so we paid special attention to making the components as small as possible to ensure they wouldn’t impact on the design of these other products. We thus purposely set ourselves the difficult challenge of manufacturing a sensor with an integrated lens. Furthermore, preparing a sensor and lens separately and then putting them together would have been a time consuming process as those in charge of the development of each part would have to carefully examine their respective specifications. In integrating the sensor and lens, we also thought we could reduce manpower in development.

Detection area, distance, and application—A total of 15 different lenses for flexible selection

What exactly is a lens?

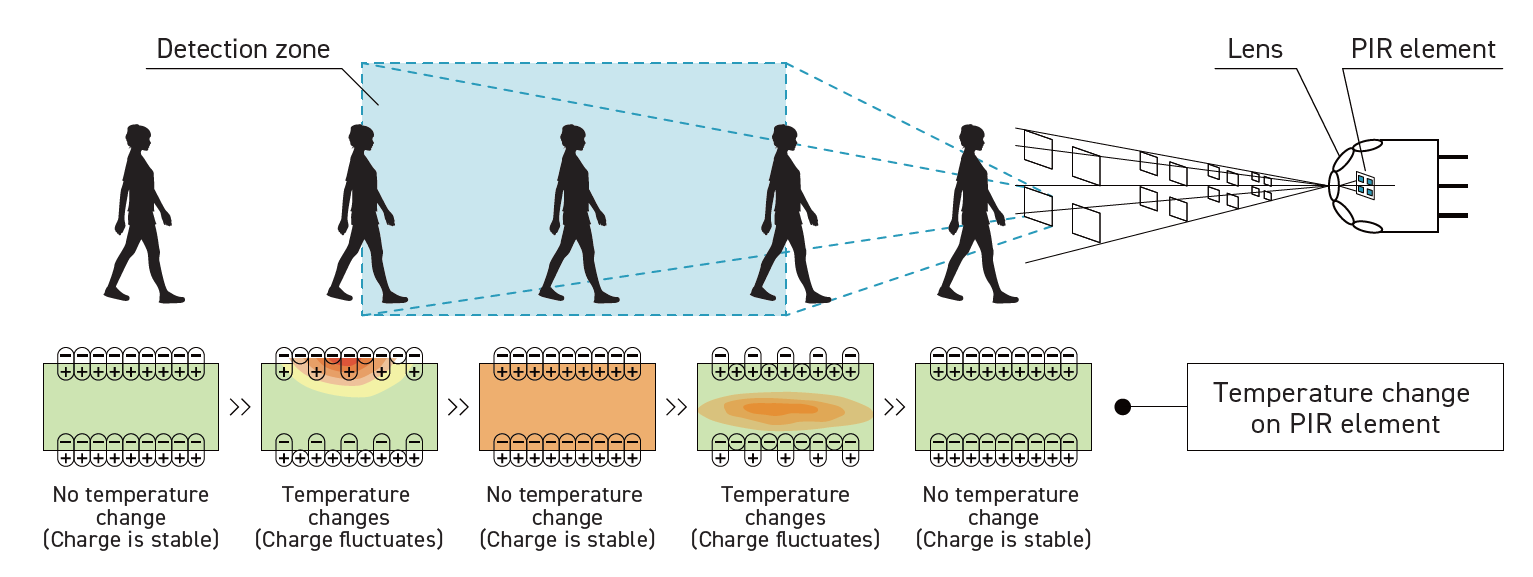

You might have noticed a small white protrusion on lighting fixtures that are compatible with motion sensors. This is the lens of the PIR Motion sensors. Lenses play a key role in helping to gathering infrared radiation to pyroelectric elements. First, the lens helps the sensor detect the infrared radiation emitted from the human body. As the infrared radiation from the human body is so weak, it is essential that this detection is highly efficient. An optical filter is also important to avoid influence from sunlight and other lighting. At Panasonic, we handle every process in-house, from the planning and design of the lens, the manufacture of the moulds, and the moulding of the lens.

Having increased your line-up of lenses, how many types do you offer now?

We currently offer a portfolio of 15 lens types that the customer can pick from depending on their application detection requirements. We have narrow area detection type, wide area detection type, long distance detection type, small movement detection type and these are all influenced by where you install our sensor.

While the outside is spherical, on the inside, numerous lenses are lined up alongside one another. At most, there can be 52 lenses inside. The more lenses there are, however, the harder it can be to control their sensitivity. The design process thus involves repeated simulations of the angle and amount of infrared radiation detected by the pyroelectric element. The thickest part of the lens is 0.8 mm, while the thinnest part is 0.2 mm. A precise mould is required to ensure lens precision, and so the moulds are mirror polished at micrometre accuracy. To maintain this accuracy, the moulds are stored in a vacuum state.

A mirror polished lens mould.

The moulds are stored in a vacuum state to prevent oxidation.

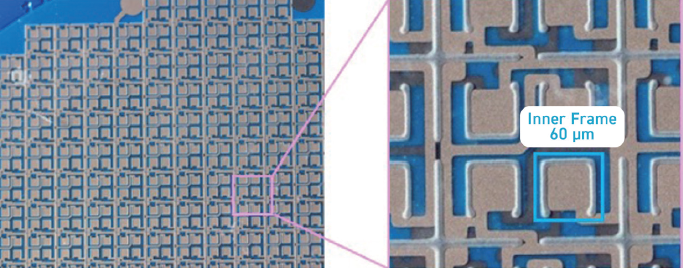

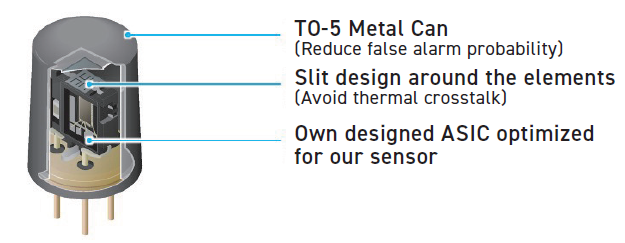

A quad pyroelectric element with a unique slit design detects marginal temperature changes for excellent sensitivity.

While conventional sensors use two pyroelectric elements, we use four. We have also created space through the adoption of a unique slit design on each element, which makes it harder for the captured heat to escape. We call this our slitted high-sensitivity quad pyroelectric element. We have also polished it down to just 50 µm to ensure that heat is quickly transferred to the element. Furthermore, while usually these elements are made from ceramic that contains lead, we use a material called lithium tantalate, which doesn’t contain lead, to do our part for the environment. We use sandblasting to create the slit design, with each slit just 60 µm in width.

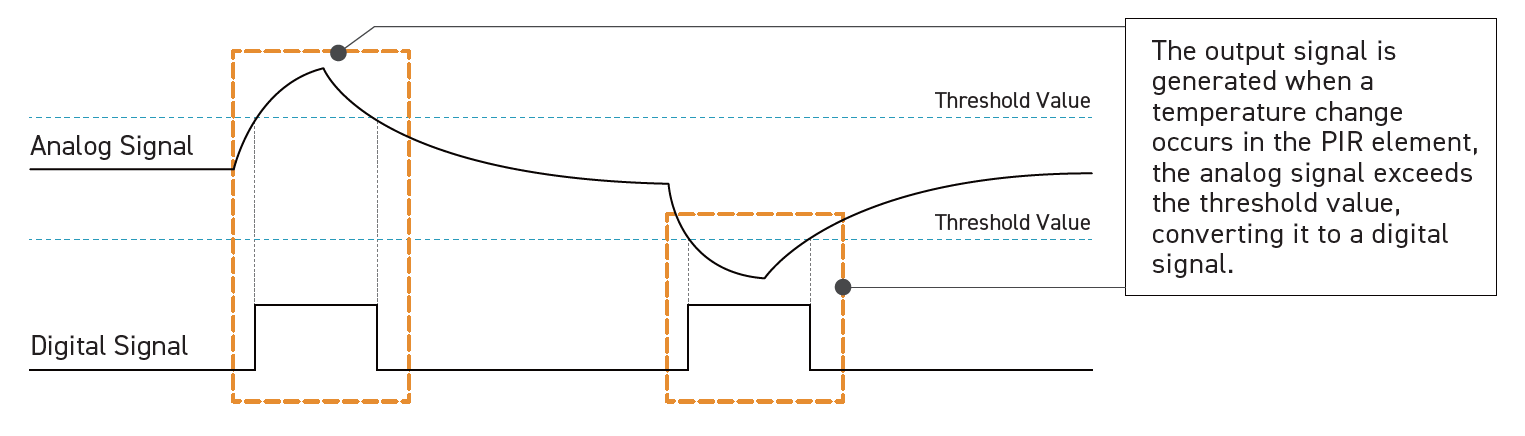

When infrared radiation enters the pyroelectric element, the changes in temperature in the element cause its surface temperature to increase. This causes the polarization within the element to change, disrupting the balance of the electrical charges attached to the element, leading to electrical charges with nothing to bind to. These electrical charges are converted into electrical signals.

Integrating the lens, pyroelectric element, and ASIC to achieve excellent ability to withstand radiation noise and manpower reduction in design.

It’s important to minimize noise as much as possible to thoroughly detect these minute electrical signals. We thus place the element and integrated circuit inside a shield known as a TO-5 Metal Can, which shields electromagnetic signals from Wi-Fi routers and mobile phones to minimize noise. In the integrated circuit we only bring together the necessary functions, using a proprietary application-specific integrated circuit, or ASIC, that contains a dedicated amp and comparator with an outstanding signal-tonoise ratio and energy-saving performance. This is all put together in one chip that fits inside the TO-5 Metal Can, minimizing noise inside the circuit and efficiently amplifying the minute electrical signals.

How did you manage to bring together so many components in such a restricted space?

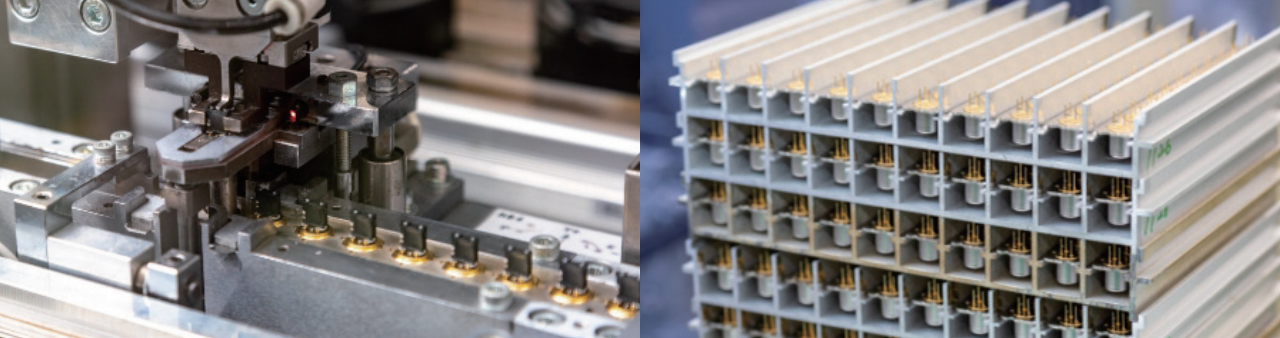

We used something called insert moulding technology, a moulding technique that binds metal and plastic. The components are placed into a metal mould, and the metal mould is then filled with plastic to form a moulded article in which the metal and plastic have become one. Insert moulding combines substances with different properties and thus requires precise accuracy, and close attention must be paid to thermal expansion and thermal conductivity.

Do the sensors ever fail to detect the minimal amounts of infrared radiation emitted from the body?

The main reason for failed detections is when there is little difference in temperature between the body and its surroundings. With PaPIRs, we guarantee detection so long as there is 4°C or more difference between the body and its surrounding environment. Regardless of the season, as long as there is a difference of 4°C or more, PaPIRs can detect the infrared radiation.

Insert moulding requires high accuracy.

Processing accuracy is checked on each sensor using an electron microscope.

PaPIRs quickly respond to market needs and continue to evolve.

Production volume of PaPIRs increased around 2017—Was there a turning point?

I think it was down to the spread of IoT. We originally thought that lighting control would be the target market for PaPIRs, but with the recent spread of IoT, demand for other applications has grown significantly. Applications have spread to entirely new products, or products that didn’t use such devices, such as motion sensors for security cameras and smart homes, or internet protocol cameras. We thus increased our line-up to include lenses for new markets, and also re-examined our production lines.

I spent two years in Germany where I worked on product development and efforts to reinforce links with the European market, which is a trendsetter in the sensor sector. In Europe, sensors are seen as paramount to improving energy efficiency, and therefore as an essential component for achieving the SDGs. As such, products of top quality are an absolute must. In line with this trend, we more than doubled our lens line-up to 15, and boosted production capacity by a factor of 1.5.

Have there been any changes in demand due to the pandemic?

Demand has grown for non-contact solutions, as people don’t want to touch switches that have been handled by others. The pandemic has also boosted IoT-related demand. There has been an increase in use with Raspberry Pis and other single-board computers too, while we have also seen a larger number of purchases through the e-commerce market. PaPIRs almost never require components to be retrofitted, and as we can provide all the functions that customers require in such a small package, customers can use the product straight after purchase as motion sensor activated on/off switches.

Perhaps most associated with motion sensors are automatic lighting fixtures. As well as for lighting in warehouses, meeting rooms, and other locations where people come and go, motion sensors can also be used to save energy by automatically turning off multifunction printers in offices and large LCDs. Recently, they have also been used at selfcheckouts in supermarkets. Elsewhere, by linking on/off conditions to the internet and visualizing the flow of people, sensors can also be used to promote the use of data mining. They can be used for security to check the presence or absence of people, to check table availability at restaurants, and visualize the availability of changing rooms or toilets. In these cases, unlike image sensors, motion sensors are non-intrusive and can protect people’s privacy.

You just mentioned image sensors. Are they ever used alongside motion sensors?

Recently we’ve seen doorbells which allow users to talk to visitors through their smartphone. As these doorbells are battery-operated, however, it’s important to minimize energy consumption. If the image sensor were to be constantly in operation, the battery would run out quickly, and the device couldn’t be used when needed. PIR Motion Sensors, on the other hand, can operate on very little energy, and the lowest energy consumption PaPIRs we have in our line-up is a 1 µA type. Using PIR Motion sensors to wake up the image sensor, for example, can ensure efficient battery use. Furthermore, as PIR Motion Sensors detect infrared radiation, they are great in the dark, and thus suitable for use as a start-up sensor.

It looks like PaPIRs can be used everywhere. What are your aims for future developments?

In manufacturing at Panasonic, we use an approach that we call the five-point design process. In this process, which includes marketing design, product design, production design, equipment/mould design, and process/management design, the relevant departments for each work closely together at all times during development. This approach began at the Tsu Factory and has been passed on to other divisions in-house. With PaPIRs, we ensure high-quality manufacturing by keeping in close contact with the marketing department to examine market trends, and by bringing together experts from each department to examine the best approach to commercialization and quickly solve any issues.

Although before researching this article we knew that PIR Motion Sensors were energy-saving devices used to turn lighting on and off, control home appliances, and operate crime prevention equipment, what we did not know was that the possibilities for these sensors were even greater. Whenever we act, there is always a trigger to that action. To turn people’s movement into data, it is important to define and interpret these triggers, and PIR Motion Sensors are an easy to way to do just that. In addition to being more compact and affordable than other sensors, with their excellent compatibility with IoT technologies, PIR Motion Sensors will no doubt become increasingly important as a key device in the upcoming data-driven society.

In visiting the factory for this report, we also realized just how reliable PaPIRs are. We were able to see once again that having lens processing technologies, moulding technologies that enable the product’s compact size, strict inspection processes, and other work all undertaken under one roof ensures toplevel quality. With the development team’s strong desire to open up new markets, 200 million units may not be too far away.