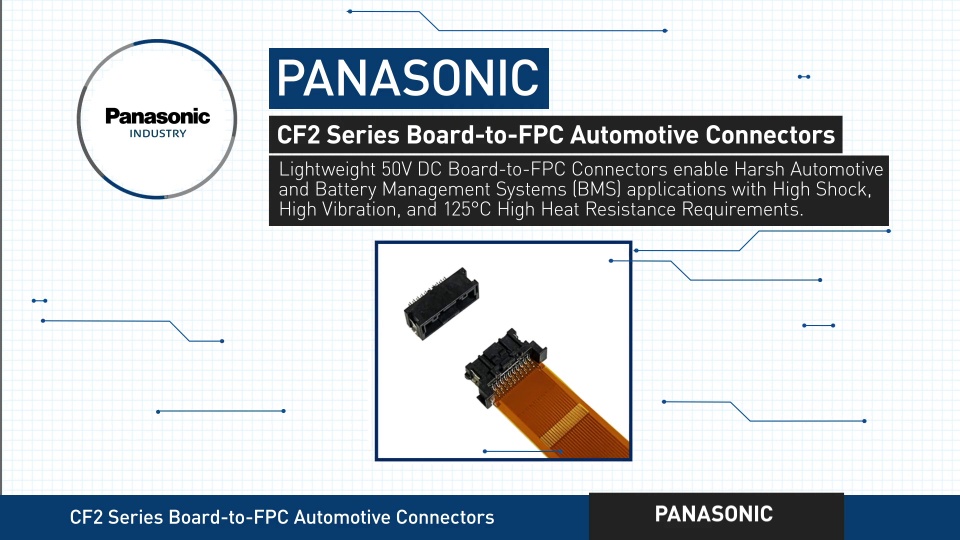

CF2 Series Board-To-FPC Automotive Connector

Lightweight 50V DC Connector Suitable for Automotive Battery Management Systems (BMS) with High Shock, High Vibration, and 125°C High Heat Resistance Requirements

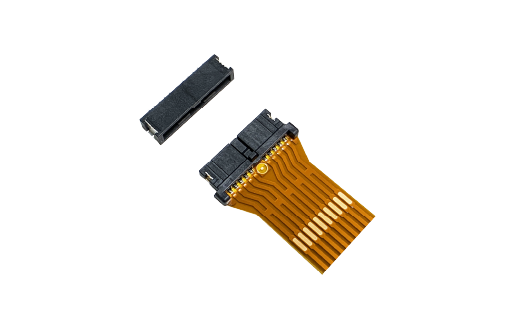

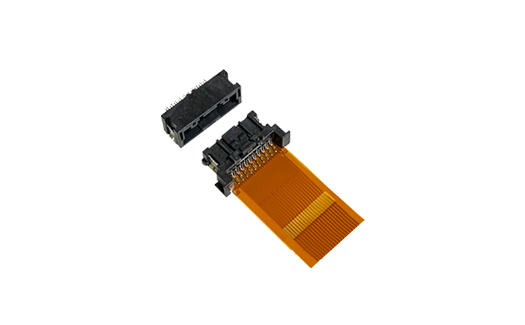

Panasonic, a worldwide leader in Connector Products, introduces the new CF2 Series Board-to-FPC Automotive Connectors.

The demand for FPC cables within automotive devices is increasing, such as instrument panels, steering switches, rear lamps, shift levers, side mirrors, headlamps, and battery management systems. Automotive applications have a growing trend to reduce the overall weight and avoid operator wiring failures caused by electrical wire connections.

Panasonic has developed the CF2 Series Board-to-FPC solution for this purpose. The new CF2 Series Board-to-FPC connection has multiple pin options (20, 28 or 32) and a 125°C heat resistance and necessary vibration characteristics suitable for the automotive and transportation market. A significant benefit is that these new Automotive Connectors can be directly connected without requiring any relay wiring harnesses when connected with FPC cables and boards for battery management systems. Panasonic's CF2 Series Automotive Connectors preserve contact reliability using a double-sided clip contact structure.

Panasonic's CF2 Series Connectors have an Inertia lock construction to prevent half-mating. Prevention of mating failure can be eliminated through Connector Position Assurance (CPA) function. The CF2 Series design also allows reflow soldering of the plug assembly to be performed simultaneously with other Surface Mount Devices without other processes where competing devices require a manual connection.

Feature and Benefits of CF2 Series:

- Number of Pins: 20, 28, 32

- Rated Current: 1.0A/Pin Contact

- Rated Voltage: 50 V DC

- Heat Resistance Up To 125°C and Strong Mechanical Shock and Vibration Resistance Using Double-Sided Clip Contact Structure

- Suitable for Harsh Automotive Applications That Require High Shock, High Vibration, and Ability to Withstand High Temperatures

- Simple and Lightweight Solution and Easy FPC and Board Connections Without Relay Wiring Harnesses

- Reflow Compatible for Simplified Assembly Process

- Prevention of Mating Failure Can Be Eliminated Through Connector Position Assurance (CPA) Function

Industries for CF2 Series:

- Automotive

- Mobility

- Transportation

Applications for CF2 Series:

- Battery Management System Wiring

- Instrument Panels

- Steering Switches

- Electronic Mirrors and Headlamps

- AGV (Autonomous Guided Vehicles) and Drones

Interested in CF2 Automotive Connectors? Contact Panasonic Now!

CF2 SERIES BOARD-TO-FPC AUTOMOTIVE CONNECTOR Features and Benefits

- Number of Pins: 20, 28, 32

- Rated Current: 1.0A/Pin Contact

- Rated Voltage: 50 V DC

- Heat Resistance Up To 125°C and Strong Mechanical Shock and Vibration Resistance Using Double-Sided Clip Contact Structure

- Suitable for Harsh Automotive Applications That Require High Shock, High Vibration, and Ability to Withstand High Temperatures

- Simple and Lightweight Solution and Easy FPC and Board Connections Without Relay Wiring Harnesses

- Reflow Compatible for Simplified Assembly Process

- Prevention of Mating Failure Can Be Eliminated Through Connector Position Assurance (CPA) Function

Part number list

Resources

New Product Information Download

Find the latest new product details here, with a convenient PDF product summary document. Quickly access and download the latest product information for the CF2 Series Board-To-FPC Automotive Connectors, including product specifications, features, benefits, industries and applications, software, block diagrams, and technical characteristics.

Playlist

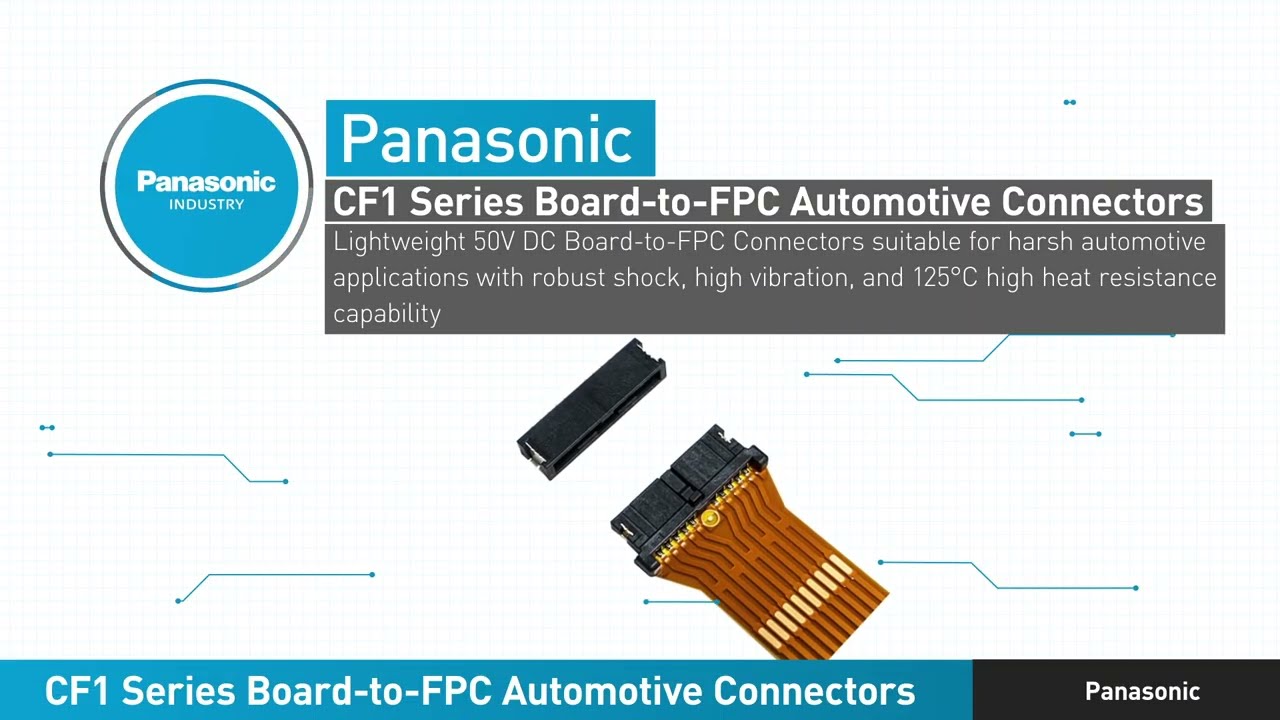

NPI: CF1 Series Board-to-FPC Automotive Connectors

New Product Brief: CF1 Series Board-to-FPC Automotive Connectors

New Product Introduction: CF2 Series Board-to-FPC Automotive Connectors

CF1 and CF2 Automotive Connectors

CF2 Series Board-to-FPC Automotive Connectors

Panasonic Automotive Solutions for Electrified Drivetrain

Panasonic Automotive Solutions for ADAS