FineX Transparent Conductive Film: Enabling Next-Gen Design with High Transmissivity and Low Electrical Resistance

Published onToday’s electronic devices are thinner, lighter, and more complex than ever before. Engineers are under constant pressure to deliver components that reduce space, weight, and power consumption — without sacrificing performance. Transparent conductive films (TCFs) sit at the heart of this challenge, powering everything from touch panels to antennas and heaters.

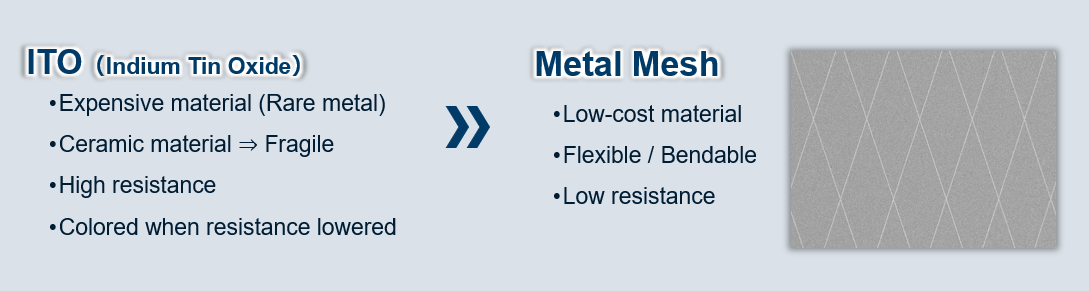

For decades, indium tin oxide (ITO) has been the go-to material. But its brittleness, high resistance, and limited design flexibility have left innovators searching for something better. Panasonic’s FineX Transparent Conductive Film (pronounced Fine Cross) is that breakthrough.

Introduction

As electronic devices become thinner, lighter, and more complex, engineers face increasing pressure to design components that can maintain performance while reducing space, weight, and power consumption. One of the most critical areas affected by this shift is the integration of transparent conductive films (TCFs). These films play a pivotal role in applications that require both electrical conductivity and optical transparency, including touch panels, antennas, heaters, and other devices.

Conventional materials such as indium tin oxide (ITO) have long been used for TCFs but present limitations in terms of brittleness, high resistance, and design inflexibility. As a result, the market has been actively seeking alternatives that can meet the increasing performance demands of modern electronics.

Panasonic’s FineX Transparent Conductive Film (pronounced "Fine Cross") answers that call. Developed using a proprietary roll-to-roll manufacturing method, FineX offers engineers a double-sided metal mesh film that delivers superior transmissivity, low electrical resistance, and mechanical flexibility—all essential characteristics for next-generation device design.

What is FineX?

FineX is Panasonic's advanced transparent conductive film designed with a double-sided complete wiring architecture. This unique structure enables electrical circuits to be patterned on both sides of the film, allowing for more complex and compact designs.

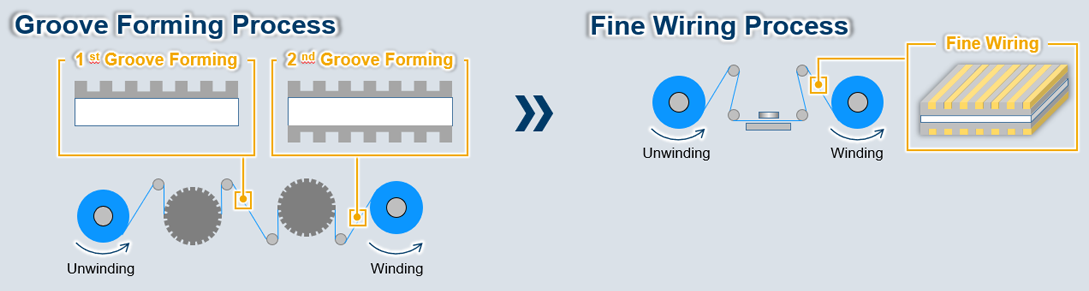

The standout innovation behind FineX is Panasonic's industry-first roll-to-roll manufacturing method. This process enables the precise patterning of ultra-fine metal mesh on flexible substrates over large surface areas, thereby improving yield, reducing costs, and enhancing product consistency. This manufacturing technique also enables Panasonic to maintain tight tolerances in line width and spacing, which are essential to achieving the film’s signature balance of high transmissivity and low resistance.

FineX delivers optical transmittance levels suitable for visual display applications, while simultaneously offering conductive performance comparable to or better than traditional ITO-based films. Its flexible construction opens new doors for use in curved, bendable, or irregular surfaces without compromising electrical integrity.

Key Technical Features

Panasonic’s FineX is engineered with six critical performance features that make it especially attractive to design engineers:

- High Transmissivity: FineX maintains high levels of optical transparency, making it ideal for use in screens, overlays, and applications requiring visual clarity. The fine pitch of the metal mesh minimizes visibility while maximizing light passage.

- Low Resistance: With finely patterned metal lines on both surfaces, FineX provides lower sheet resistance compared to traditional TCFs. This ensures reliable current flow even in low-voltage systems.

- Bendability: The flexible substrate and roll-to-roll metal mesh construction allow the film to bend and conform to three-dimensional surfaces. This makes it suitable for wearables, automotive interiors, and foldable devices.

- Design Flexibility: Engineers can customize circuit layouts and mesh patterns to meet the specific electrical and mechanical requirements of each application. FineX supports high-resolution designs that enable greater functionality in constrained spaces.

- Powerful Conductivity: The double-sided wiring embedded in the grooves provides greater current-carrying capability without increasing thickness or decreasing transparency. This is especially important for heaters, antennas, or components with high current demands.

- Efficiency: The lightweight and scalable nature of the film reduces material usage and simplifies integration into complex assemblies. Combined with its high conductivity, FineX supports energy-efficient device design.

Differentiating Advantages

Three Primary Differentiators

- Superior Transmissivity: Panasonic's precise control over mesh patterning allows FineX to achieve exceptional transparency with minimal visual distortion. This is vital for display-integrated applications where screen visibility is critical or where it is necessary to not interfere with the design/visibility of the product.

- Lower Resistance: The use of ultra-fine metal wiring on both sides dramatically lowers resistance, ensuring reliable signal transmission and power delivery across the surface.

- Mechanical Flexibility: FineX's ability to flex and conform to curved surfaces sets it apart from brittle ITO films and rigid alternatives. This makes it a strong candidate for flexible displays, automotive HMIs, and advanced industrial designs.

Top Application Areas

Transparent EMC Shield

FineX can be used as a transparent electromagnetic compatibility (EMC) shield to block EMI while allowing light transmission. This is particularly useful in display-integrated electronics and medical equipment where shielding is required without sacrificing visibility.

Transparent Heater

FineX's low resistance and high conductivity enable efficient heat generation across transparent surfaces. Ideal for automotive windshields, camera lenses, or sensor housings, these heaters prevent fogging or icing while maintaining complete visibility.

Transparent Antenna

The double-sided wiring architecture enables FineX to function as a transparent antenna, allowing for wireless communication in 5G, IoT, and automotive systems without obstructing device aesthetics or displays. FineX supports high-frequency performance with low loss.

Transparent PCB

For applications requiring circuit visibility or light passage through the board itself, FineX enables the creation of transparent printed circuit boards. This opens possibilities for educational devices, smart windows, and design-conscious consumer electronics.

Touch Sensor

FineX supports capacitive sensing technologies through its fine metal mesh layout. It enables the development of high-performance touch interfaces used in industrial controls, consumer products, and automotive HMIs.

Optical Devices

FineX can be used to mount LED’s. This makes it perfect for applications such heads up displays on automotive windshields or wearable devices. It can also be used as a light control device for allowing light through or dimming/shading for applications such as automotive sunroofs.

Each application demonstrates the multifunctional potential of FineX, combining electrical performance, optical transparency, and mechanical adaptability.

Panasonic’s Manufacturing Breakthrough

At the heart of FineX’s capabilities is Panasonic’s proprietary roll-to-roll manufacturing technique. Unlike traditional batch processes, which limit throughput and consistency, this method enables the continuous production of ultra-fine metal mesh patterns across long film lengths.

Key benefits of this approach include:

- Scalability: Suitable for both mass production and prototyping, FineX is available in roll format for easy integration.

- Uniformity: Maintains tight tolerances in line width and spacing, ensuring consistent electrical and optical performance across the entire film.

- Precision: Enables extremely fine feature sizes, which are critical for modern, miniaturized electronics.

This process also allows Panasonic to deliver FineX with high production efficiency, meeting the cost and volume demands of a wide range of industries.

Conclusion

The evolution of modern electronics demands materials that can keep pace with rising expectations for performance, design freedom, and integration. Panasonic’s FineX Transparent Conductive Film provides engineers with a breakthrough solution that balances high light transmissivity, low electrical resistance, and mechanical flexibility.

By leveraging its double-sided wiring architecture and roll-to-roll manufacturing process, FineX enables a wide range of applications, including transparent heaters, antennas, EMC shielding, and flexible touch sensors.

As the need for transparent, flexible, and conductive materials continues to grow, FineX stands out as a versatile and future-ready choice. Engineers are encouraged to explore the full potential of FineX through Panasonic’s online resources, technical datasheets, and distribution partners.

Loading form