FPC Connector Technology

Published on- Connectors

Flexible Printed Circuit (FPC) Connectors are the ideal option for customers interested in smaller capacity heights. With terminal pitches ranging between 0.3mm to 0.5mm, and mounting height from 0.9mm to 1.8mm, these connectors can be used in a wide range of digital device applications.

PANASONIC FPC CONNECTORS

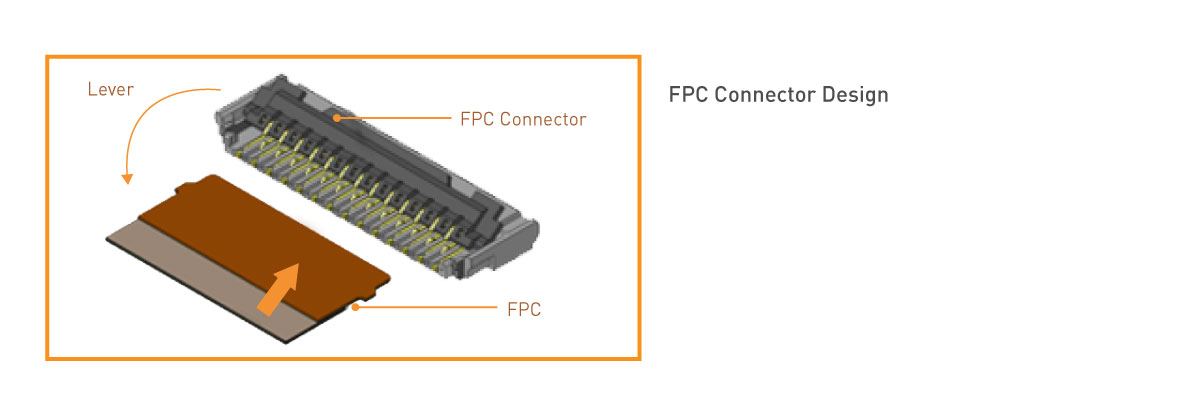

An FPC Connector, which is sometimes called a Zero Insertion Force connector, is a high-performance connector that is soldered to a PCB and locks a Flexible Printed Circuit (FPC) cable in place by closing a mechanical lever. The low profile and slim size of these connectors is ideal for customers that are trying to make products miniaturized. Generally, wiring patterns can be placed underneath this type of connector.

Three Key Features Of FPC Connectors

1. Back-lock Structure

One common feature of all Panasonic FPC connectors is that they all employ a back-lock structure. Compared to traditional front lever types, a back-lock structure tends to have a higher horizontal pulling force once locked. This means that the mechanical locking lever of the connector is located at the opposite side of where the FPC cable is inserted. This prevents a common failure mode found among front lever types where any upward bending of the FPC may risk an unintentional re-opening of the lever.

Another benefit of the back-lock structure is that this allows for the connectors to be delivered in the opened position whereas front-lock FPC connectors are typically received with the lever in the locked position. This is helpful by reducing the number of steps on the production assembly line required to insert the FPC allowing for fewer man-hours and higher efficiency during mass production.

One final feature of our back-lock structure is that there are four molded walls of the FPC inlet which assists in creating a smooth insertion and preventing displacement of the FPC once inserted.

2. Top and bottom contacts

Another characteristic of a Panasonic FPC connector is that they contain both top and bottom contacts. Depending on the FPC wiring conditions, this will eliminate the need for choosing between a top or bottom type contact connector and grants more freedom of design when making potential necessary changes to the board layout. This may also prevent mistakes on the production line from inserting the FPC cable upside down.

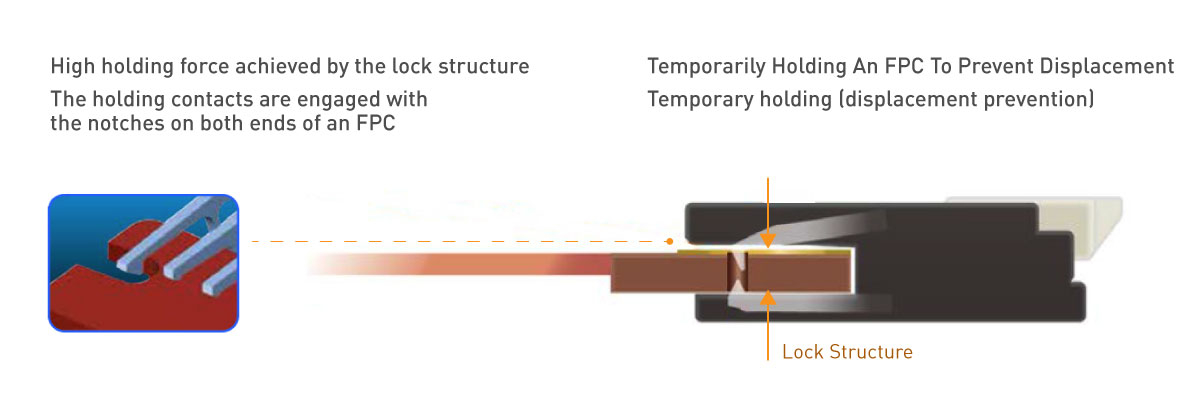

3. FPC Holding Contacts For Y5BW

Panasonic’s Y5BW series connectors contain special FPC holding contacts which temporarily hold the inserted FPC in place before locking the lever. The holding contacts would be engaged when using an FPC cable with notches cut on both ends which allows the pins to fall into the notches when the FPC cable is fully inserted. In addition to preventing displacement of the FPC during assembly, these holding contacts also have the added benefit of providing additional horizontal pulling strength to the connector during use.

Another specialty series within the Panasonic FPC connector line-up is the Y5BH series which is designed for high-speed transmission. This is a 0.5mm pitch connector that maintains 85- and 90-Ohm differential impedance matching for up to 10 Gbps speed. This series does not designate pin assignments which provides a higher degree of design freedom to users for custom configuration. Lastly, the Y5BH is not only compliant with major high-speed transmission standards using FPC cables but is also compatible with Flexible Flat Cables (FFC) as well for more cost-effective designs.