Advanced Component Technology for Solar Energy Equipment

Published on- Relays & Contactors

- Capacitors

The solar energy market is growing rapidly as more governments, organizations, and households shift towards renewable energy sources in response to the ongoing climate crisis. With the increasing installation of photovoltaic (PV) generator panels at residential and grid scales, battery energy storage systems (ESS) are also being deployed to optimize the financial return on solar energy equipment and ensure clean energy availability even when the sun is not shining.

The Crucial Role of Advanced Components in Solar Energy Efficiency and Reliability

Advanced component technology plays a crucial role in improving the efficiency and reliability of solar energy equipment. Solar panels require high-performance components such as microinverters, power optimizers, and monitoring systems to maximize energy output and ensure safe operation. By integrating advanced components with solar energy equipment, engineers can improve energy efficiency, reduce operational costs, and extend the lifespan of solar systems.

As more energy equipment manufacturers compete for market share, they pay close attention to the features and specifications of specialized switching, protection, and filtering components that handle high currents and voltages in energy equipment. This blog article highlights the importance of safe operation, long lifetime, and superior performance regarding the preferred components for these crucial functions in solar inverters and ESS.

The Advantages of Decentralized String Inverter Arrangements and Specialized High-Current Relays

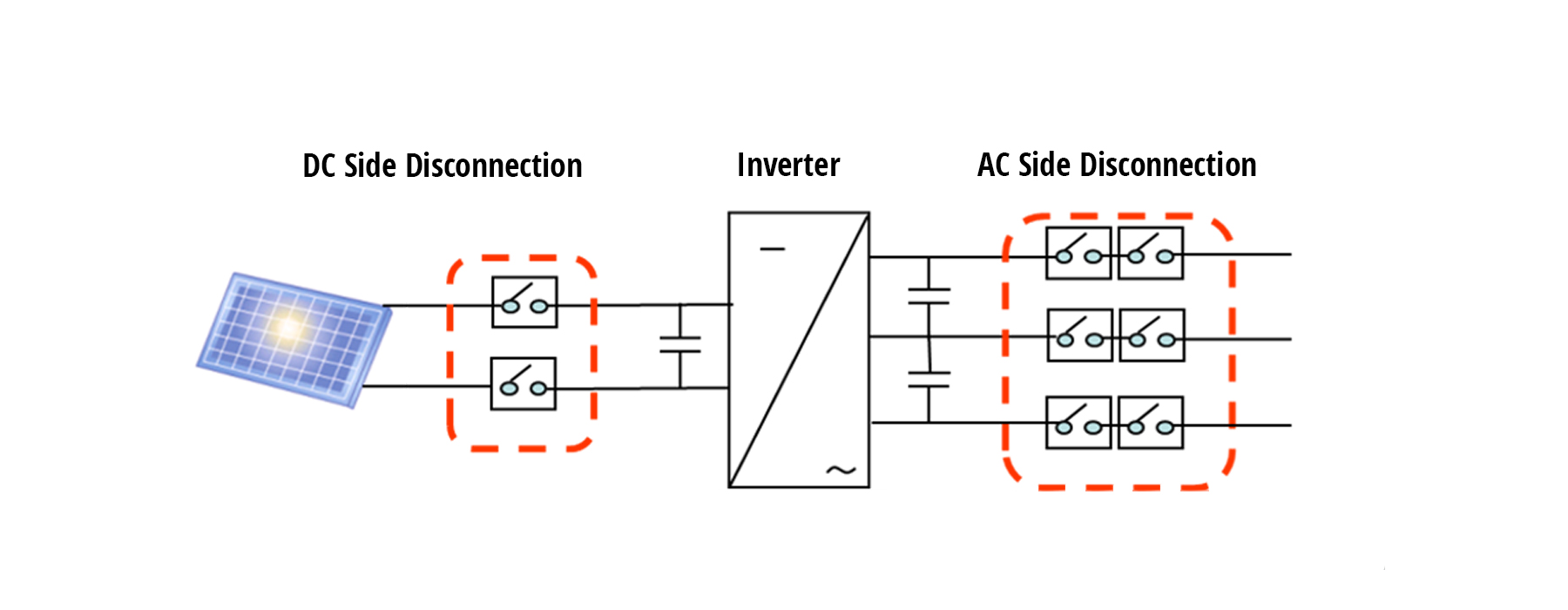

The PV inverter comes in various shapes and sizes, from residential rooftop installations to vast solar farms. One exciting development is the decentralized string inverter arrangement in large solar arrays. Traditionally, the output from these arrays was fed into a single, centralized inverter, in which a contactor was often used to cut off power to its AC side. To increase the inverter's efficiency, solar system operators are now implementing a distributed topology, replacing a single central inverter with as many as three smaller string inverters, each rated for less than 100 kW.

OPTIMUM RELAY CONFIGURATION FOR SOLAR INVERTERS

When splitting the panels' output across multiple inverters, the switched current at each inverter falls to a level where a specialized high-current relay can potentially handle it. Panasonic's HE-N Series Relay, with a current rating of 120 A at 480 V AC, is suitable for systems with string inverters rated for power output up to 100 kW. This Relay offers cost- and space-saving opportunities. It is an attractive alternative to a contactor since it can be board-mounted using automated assembly equipment, making it a more efficient, simpler, and cheaper production process. The Relay is smaller than a contactor and often has a lower unit cost. The HE-N Series Relay is well-suited to high-current applications, with a creepage and clearance distance of 10.5 mm, a contact gap of a minimum of 3.6 mm, and certification according to specifications applied by UL, C-UL, and VDE.

How Panasonic's Film Capacitors Are Driving the Solar Energy Equipment Industry Forward

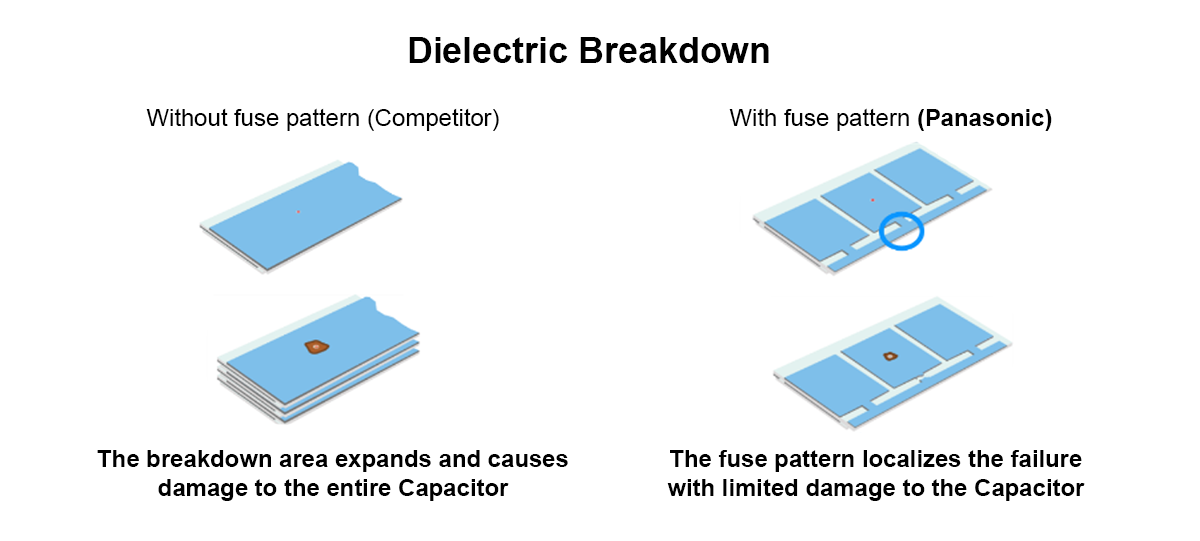

Our Film Capacitors are also in the spotlight as inverter manufacturers aim to promise higher reliability and longer operating lifetimes. The EZP-V Series of Film Capacitors performs filtering functions at the high-voltage DC input and DC link stages of an inverter, handles a voltage range spanning 450 V to 1,100 V DC, and is available in capacitance values ranging from 3 µF to 110 µF. These devices have three features that strongly support the OEM's effort to extend the lifetime and increase the reliability of PV generation equipment, which may be expected to produce power for a minimum of 25 years:

- Unlike conventional Film Capacitors, the unique fuse pattern embedded in Panasonic Film Capacitors means that a breakdown in one part of the dielectric does not disable the entire device. Instead, it can continue to operate with reduced capacitance.

- The Capacitor's failure mode is open rather than short, meaning that it fails safely rather than in an over-current event, with its attendant risks of overheating and burning.

- The EZP-V Series is tolerant of high humidity, an essential feature for equipment installed outdoors in an uncontrolled atmosphere.

Ensuring Safety in Solar Energy: The Crucial Role of Cut-Off Devices and Relays in ESS Equipment

After energy from the sun is converted to AC electrical power by the inverter, what is not used instantly may be diverted to the grid or stored in an ESS. The ESS option is becoming increasingly popular for householders as it increases independence from the grid and can reduce total energy costs in the long term. At the grid scale, deploying ESS installations provides part of the answer to the intermittency of solar and wind renewable energy sources.

Developing reliable ESS equipment requires careful attention to safety and circuit protection due to the high voltages and currents passing between the inverter, the ESS, and end-use equipment. In the US, the National Electric Code standard NEC2014 690.12 requires an emergency cut-off device controlled by a relay to be installed near a solar panel array to protect the safety of first responders in an emergency.

The HE-V Series Relay is ideal for this application since it can cut off both positive and negative lines on the DC side of the inverter. The Relay ensures safe operation as it dissipates electrical arcs generated by switching operations upwards along the insulated walls of the Relay using a blow-out magnet mechanism and serial contact connection. The Relay's low coil holding power of 210 mW also helps to reduce fire risk by minimizing system power consumption. The 3.8 mm contact gap and large creepage and clearance distances provide for compliance with IEC regulations governing the rapid shutdown application.

Safety cut-off Relays are also used in the battery system. When a large inverter supplies the battery, a smoothing capacitor on the input side prevents voltage fluctuations when a large load is connected to the AC side. The large size of this Capacitor results in a high inrush current, which can lead to contact welding in the safety relay; for safety relay applications with a risk of contact welding, Panasonic supplies special Relays that include built-in contact welding detection capability. The HE-S and HE-R Series miniature Relays feature an auxiliary 1FormB contact to create a safety circuit.

Safety and Reliability in Energy Storage with PhotoMOS

The battery ESS requires further safety functions. If the battery's insulation deteriorates, a ground fault might occur, which can be dangerous to people nearby or could result in equipment damage. A Panasonic PhotoMOS Semiconductor Relay responds to a ground-fault current by switching on a current sensor that can provide a fault signal to the control unit. A second use of a PhotoMOS Semiconductor Relay is monitoring the charging voltages of a group of battery cells. Voltage monitoring is an essential battery management system (BMS) function. A PhotoMOS device offers the advantages of small size, unlimited switching cycles for a long operating lifetime, and high-quality products for robust performance and a long operating lifetime.

The solar energy applications described in this article demand the ability to maintain safe operation in a high-voltage, high-current environment while offering the equipment manufacturer the advantages of reliability and long lifetime. Panasonic products have a long track record of superior performance and reliability resulting from innovative design, advanced production techniques, and high-quality materials. The film capacitors and relays highlighted in this article are consistent with this track record and promise high-reliability characteristics such as humidity resistance in film capacitors and long cycle life in relays.

Solar Storage Solutions with Panasonic Industry & Energy

In today’s environmentally conscious world, Solar Storage is an increasingly popular system that captures energy and stores it to perform operations in the future. These Systems involve converting many forms of energy, such as electrical potential energy or kinetic energy, into more economically storable formats for short-term and long-term use. Panasonic product solutions include Relays, Passive Components, such as Capacitors, Metal Oxide Varistors, and more.