Measurement Sensors: Specular vs Diffuse

Published on- Sensors

Have you ever wondered why some Measurement Sensors can only be used on dull surfaces (e.g. thread depth measurement on a tire), or only on shiny surfaces (e.g. thickness measurement of glass)? In order to fully grasp the concept, some basics about reflection must be covered. Let’s get some background information on reflection.

Measurement Sensors and Reflection

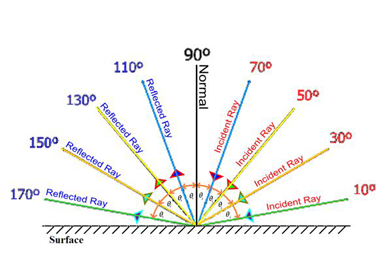

When light hits a surface, some light is absorbed, and the rest is reflected. The reflected light is subject to the law of reflection, which states the angle of incoming light (incident ray) is equal to the angle of outgoing light (reflected ray), produced at the same angle with respect to the line normal (vector perpendicular) to the surface.

A normal line is drawn perpendicular to the surface with the angle of incidence being between the normal line and the incident ray. The angle of reflection is the angle between the normal line and the reflected ray. The reflected ray and the incident rays are on opposing sides of the normal line.

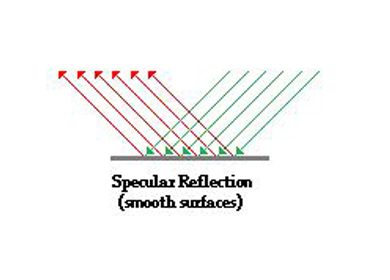

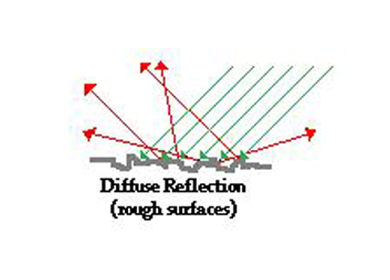

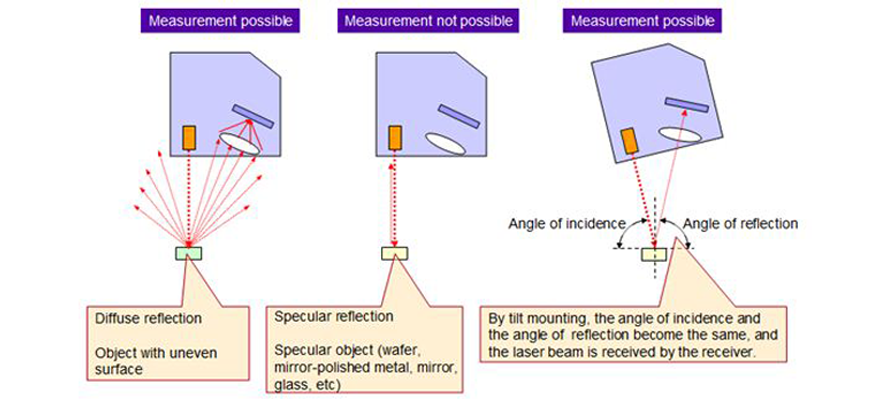

The key concept here is that the reflection is independent of surface orientation, and the law of reflection is always observed. The reflection angle can be measured with respect to line normal to the surface. With reflection, there are two different types of surfaces: smooth surfaces and rough surfaces. If a series of light rays was to reflect off a smooth surface, they would all reflect in the same direction, yielding a specular reflection. If a series of light rays was to reflect off a rough surface, the light rays would reflect in different directions due to various orientations of the rough surface.

Surface Dependent Reflection

So, what does that all mean? Simply put, the type of reflection depends on the surface. A smooth, flat surface will yield specular reflection, while a jagged, rough surface will yield diffuse reflection. That’s why a person can see their reflection in a placid lake, and not see a reflection off pavement. The answers to why Measurement Sensors can either only see dull or shiny surfaces lay within the angle of reflection.

The Angle of Reflection

Each Measurement Sensor is set up to see reflection at a specific angle. Our specular reflective Sensors are meant to measure objects like glass. They look for the received light at the same exact angle in which the laser shoots light rays, emitting laser shoots incident rays at an angle away from the line normal to the surface. While our diffuse Sensors are set to read the incident ray, it is at a diffused angle (emitting laser shoots incident ray perpendicular to the surface) reflecting off an uneven surface. If a diffuse Sensor was to be used on a specular object, the light would be reflected directly back to the laser, and not to the sensing element. If you were to use a specular Sensor on an object such as a tire, the reflected light would be diffuse and never reach the sensing element.

Have you seen an unusual use of a diffuse or specular Sensor that might lose accuracy because of this effect? Write about your experience in the Comments section below.