Temperature Controllers Using Hysteresis

Published onA temperature controller is a device that one can employ to provide a consistent temperature in their process. Panasonic Temperature Controllers have a PID function to calculate an appropriate counter response to fluctuations in the process.

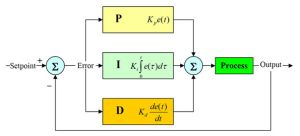

PID involves three separate constant parameters: the proportional, the integral and derivative values, called P, I, and D. Think of the algorithm as measuring present errors, accumulation of past errors, and prediction of future errors based on the current rate of change. The weighted sum of these three measurements is used to adjust the process as necessary to reach and sustain a set value (SV) typically in temperature.

Panasonic Temperature Controllers provide heating and/or cooling action, as well as an auto-tuning process. The auto-tune process will vary the output of the controller (on/off, or low to high) and monitor the change in response of the process (typically temperature). After monitoring is complete, the controller has calculated an optimal set of PID values to reliably control the process.

Note that every process will have its own optimal PID constants. System or process stability is only as good as the PID constants and the PID algorithm used. In applications where stability based on a specific value (SV) is not critical, a Hysteresis can be used instead. Hysteresis does not use a set point it uses a range for process control action.

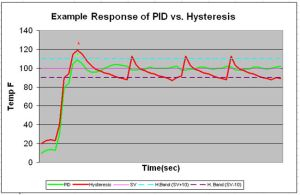

For example, instead of controlling the process precisely to a SV of 100°F, we can have the controller respond when the present value (PV) is +/- 10°F from SV. This gives us a 20 degree band for hysteresis response.

The first diagram uses setpoint control, like PID, verse band control, like hysteresis. The pink line is the setvalue at 100°F. This is the value at which our green wave PID is struggling to hold. This means that the PID is constantly working to keep the process at 100°F. During this time, the output is constantly oscillating. The hysteresis behaves quite differently, while also keeping the temperature around the SV.

Notice after the first overshoot (see the asterix on the diagram in Fig. 2) the red line, hysteresis, will only turn on again until the temperature drops out of the lower constraint in purple. Hysteresis will constantly turn the output on until the temperature rises above the upper constraint (represented by the blue line). Both of these controls have advantages and disadvantages.

Pros & Cons

|

PROS |

CONS |

|

|

Hysteresis |

|

|

|

PID |

|

|