Panasonic's TDC Series POSCAP™ Conductive Polymer Tantalum Solid Capacitors are ideal for environments requiring extremely high temperatures combined with high endurance of up to 1,000 hours.

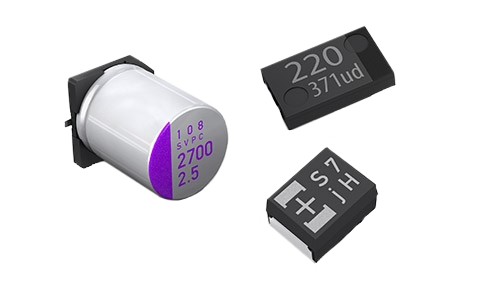

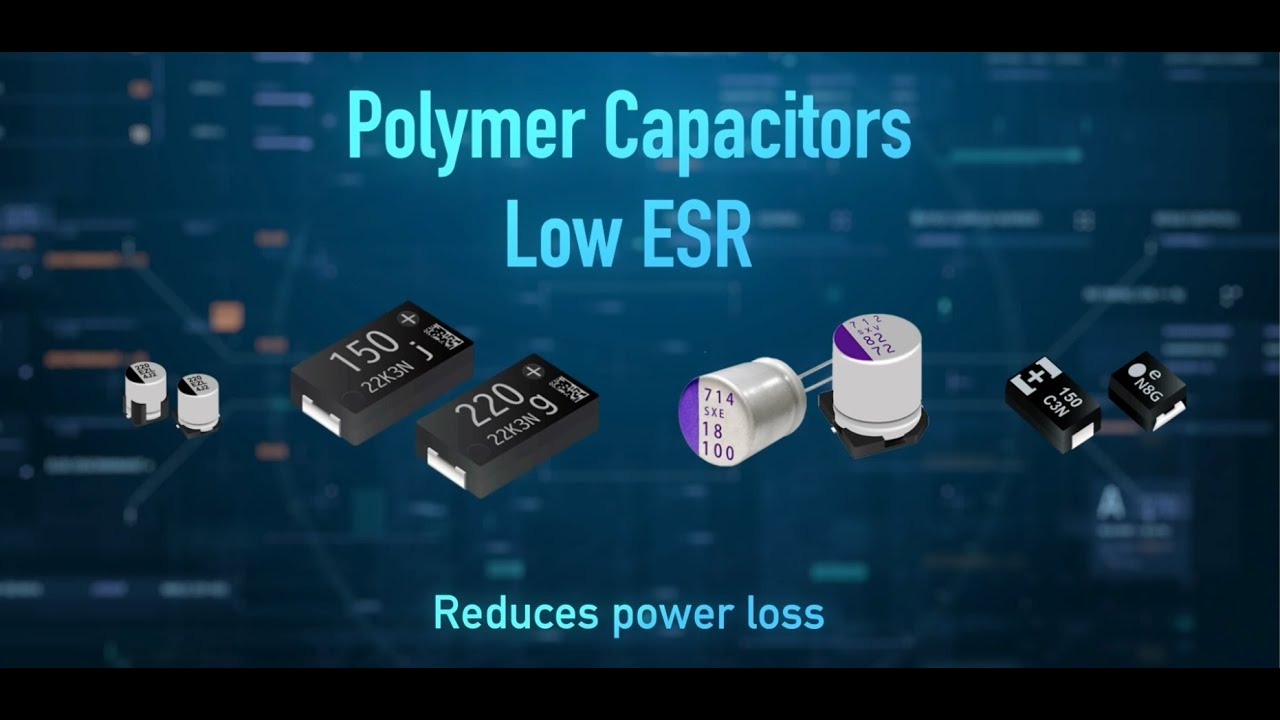

POSCAP™ Capacitors utilize sintered tantalum as an anode system and a highly conductive polymer created with Panasonic's unique method as a cathode system. This enables POSCAP™ Capacitors to be thin, small, and at the same time, have low ESR (Equivalent Series Resistance) and superior high-frequency characteristics. These features make POSCAP™ Capacitors one of the best digital/high-frequency applications candidates.

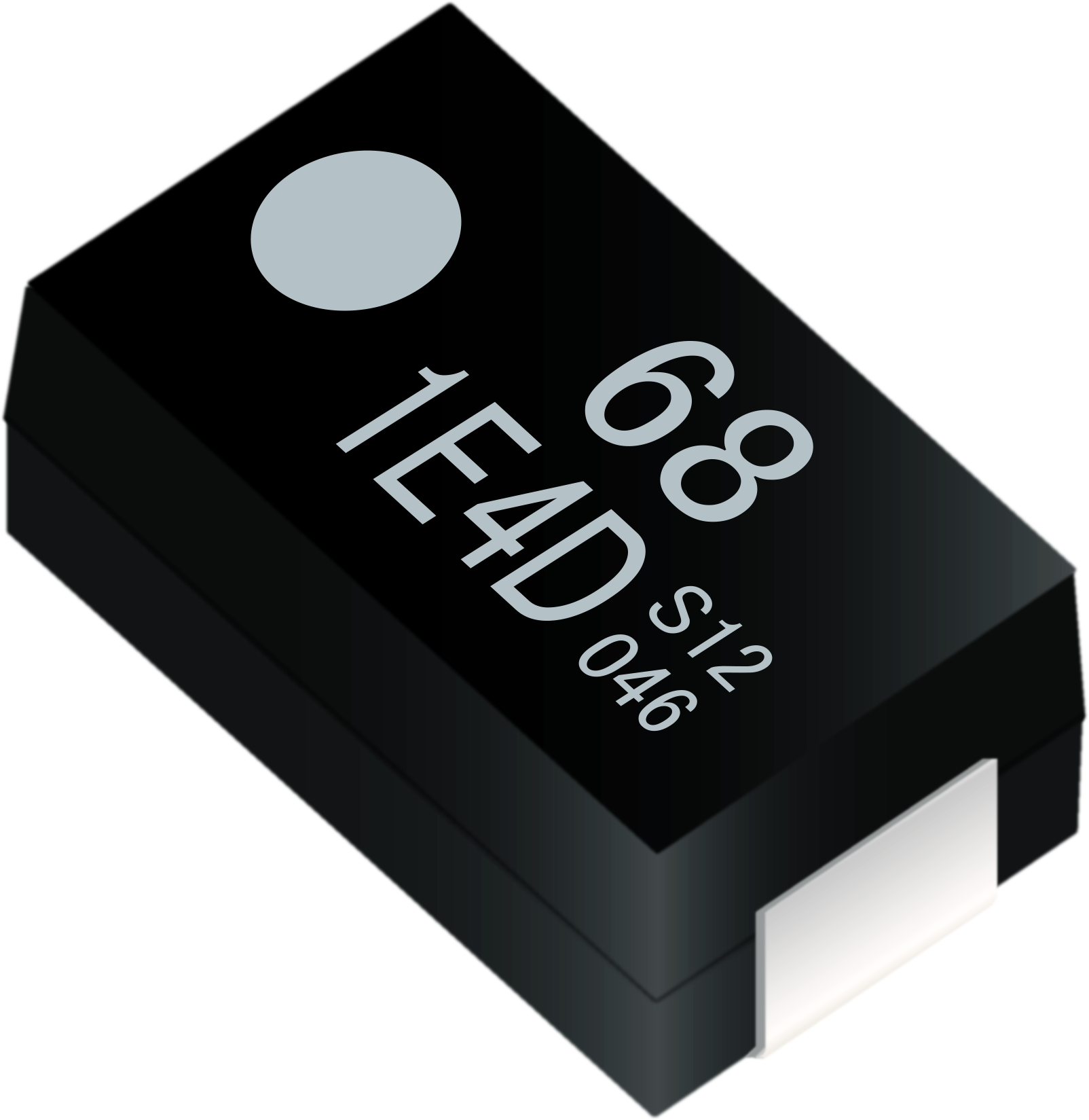

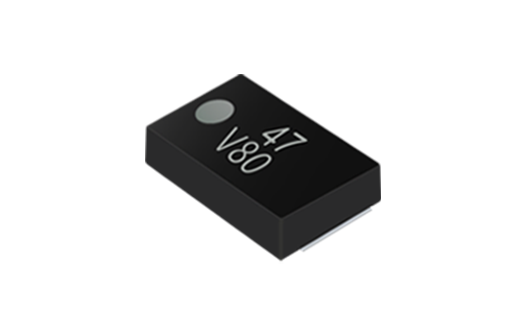

The TDC Series can withstand 125°C for 1,000 hours with a wide capacitance range of 15uF~150uF, and its high reliability within tough applications makes it an ideal Capacitor for usage in servers, base stations, and industrial applications.

B2 case size parts comply with JEDEC reflow condition.

Features and Benefits of TDC Series

- Small Size: 7.3 x 4.3 x 3.0mm

- High Voltage

- Large Capacitance

- High Temperature / Long Life: 1,000 Hours at 125°C

- Noise Reduction

- Smoothing Voltage for Power Line

- Suitable for High Load Current Applications

- Temperature Range: -55°C to 125°C

- Halogen Free

- RoHS Compliant

Applications oF TDC Series

- CPU/GPU

- Base Stations

- USB Type-C

- Accelerator

- Ai/Edge Server

TDC Series

Part number list

Resources

New Product Information Download

Find the latest new product details here, with a convenient PDF product summary document. Quickly access and download the latest product information for the TDC Series POSCAP™ Capacitors, including product specifications, features, benefits, industries and applications, software, block diagrams, and technical characteristics.

Stay up to date

Playlist

Panasonic Industrial Solutions for 5G Networking Applications

New Product Spotlight: TQC Series POSCAP™ Capacitors

NPI: TQC Series POSCAP™ Capacitors

New Product Introduction: TLE/TDC Series POSCAP™ Capacitors

New Product Information: TQT Series

Panasonic Capacitor Solutions for Data Center, Edge and AI Servers