Revolutionizing Industrial Controls with PhotoMOS® Solutions

Published on- Relays & Contactors

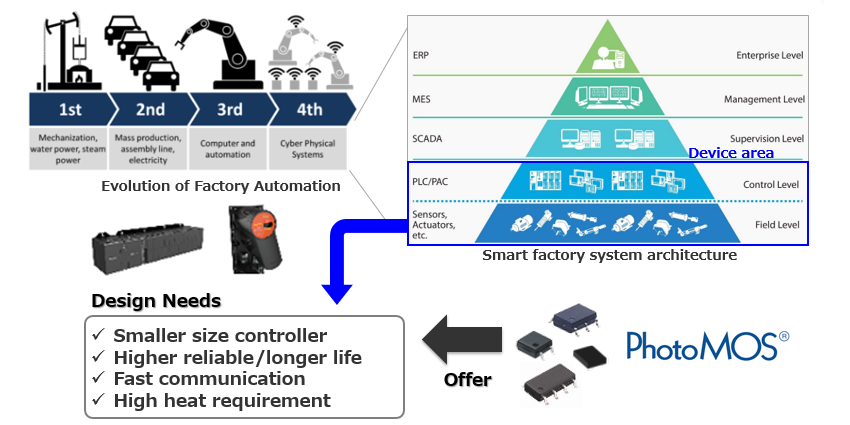

The evolution of Industry 4.0 has created a demand to further introduce factory automation by adding more connectivity, communication, safety, and automation. These factors relating to manufacturing improvement are met through the integrations of new technologies such as IoT, Artificial Intelligence, and cloud computing to enhance the system’s capabilities.

The Shift To Smart Factories

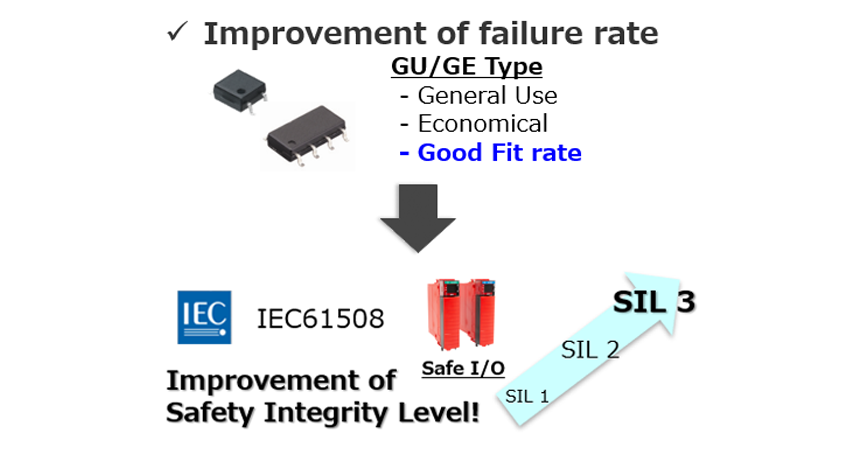

Improvement of Failure Rate

The PhotoMOS® GU/GE (general use and general economy) type solutions are commonly used for switching signals of the analog to digital converter found in distribution control systems. These PhotoMOS feature an extremely low failure rate to increase reliability Integrity levels found within safety I/O devices according to international safety integrity standards such as IEC 61508.

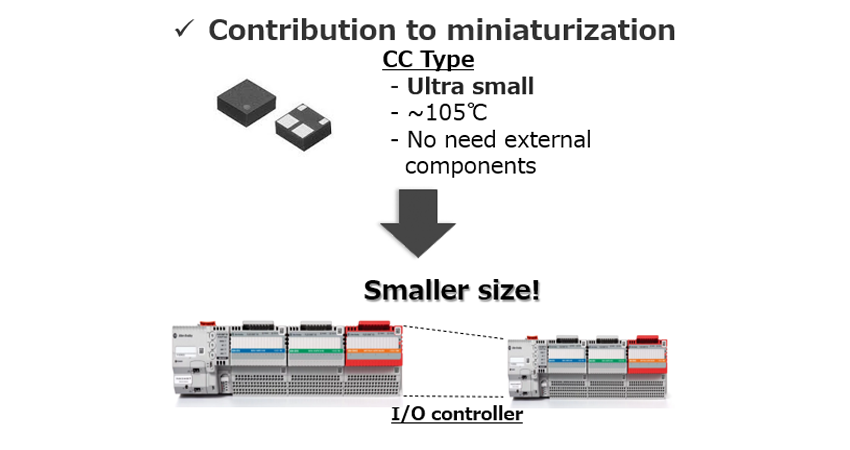

Contribution to Miniaturization

Another solution would be Panasonic’s capacitive coupled isolation technology. PhotoMOS devices feature a capacitive coupled driving circuit, a patented technology unique to Panasonic. Unlikely optically coupled LED-driven devices, the Capacitive Coupled technology is equipped in the smallest package size (TSON), with external dimensions of only 1.8 x 1.95 x 0.8mm. Additionally, this PhotoMOS device features a low input current of 0.09mA (typical) for power savings and a higher ambient temperature rating of up to 105 degrees Celsius. With its ultra-small package size, this product contributes to overall system miniaturization.

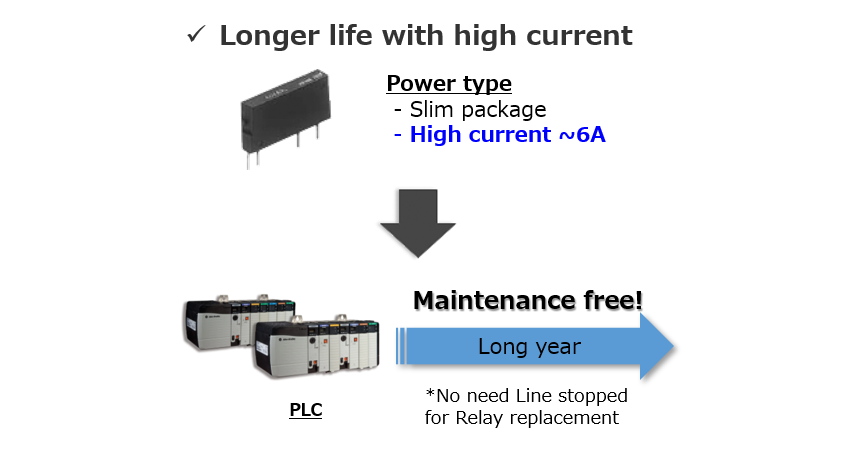

Longer Life with High Current

Lastly, when considering longer life with high current capabilities, Panasonic offers a Power type PhotoMOS Relay which is an excellent replacement for traditional mechanical relays. PhotoMOS devices can be used in the Analog to Digital input module to provide insulation for each channel. These devices offer current capabilities up to 6A and unlimited switching life to provide a maintenance-free and highly reliable functioning system with faster switching capability for speedy operation. PhotoMOS can also be used to replace transistors on the PLC's output control module, which eliminates a common failure mode due to the miswiring of the transistor.

In summary, Panasonic's PhotoMOS Relays shine in the factory automation market due to emerging trends from Industry 4.0 and the increasing need for high reliability, small size, and fast switching response time.