Revolutionizing HVAC Outdoor Units: Panasonic's Compact Motor Development

Published on- HVAC/R & Appliance Devices

Panasonic developed a new motor for side-discharge HVAC outdoor units that reduce the number of motors needed while maintaining performance and a low profile. The latest fan motor has increased performance at a similar size, allowing the system to consolidate to a single fan motor instead of the standard 2-motor installation. This reduces the size and weight of the HVAC system. The engineers redesigned the motor core magnetic structure and magnets, increased the number of poles in the magnetic circuit, and adopted anti-vibration material to achieve this. The new motor reduces ergonomic workload and makes transportation less laborious for workers. Panasonic's commitment to delivering products that benefit society continues to make waves in the tech industry.

The Challenge: Reducing Fan Motors

Panasonic has been making waves in the technology industry for decades. From televisions to cameras, the company has established itself as a pioneer in consumer electronics. Panasonic recently released a case study detailing the development of a new motor for side-discharge HVAC outdoor units. The objective was to reduce the number of motors used in the outdoor unit by developing a motor with 20% more output than a conventional motor of the same size. The motor reduction was made to alleviate the ergonomic stress of manual transportation, which can be laborious and exhausting due to the large and heavy conventional units. By developing a fan motor with increased performance at a similar size, the outdoor system can now consolidate from the traditional installation of a 2-motor to only a single fan motor, reducing the HVAC system's size and weight.

Redesigning Motor Core Magnetic Structure

To achieve this objective, Panasonic engineers completed a redesign of the motor core magnetic structure, which was a challenging task. In concept, consolidating to only one fan motor in the outdoor HVAC system would require a larger motor and fan to keep the same air volume output. However, using a larger motor would conflict with the new design concept by increasing the weight of the outdoor unit. A deeper look and approach to the motor design were necessary to solve this problem.

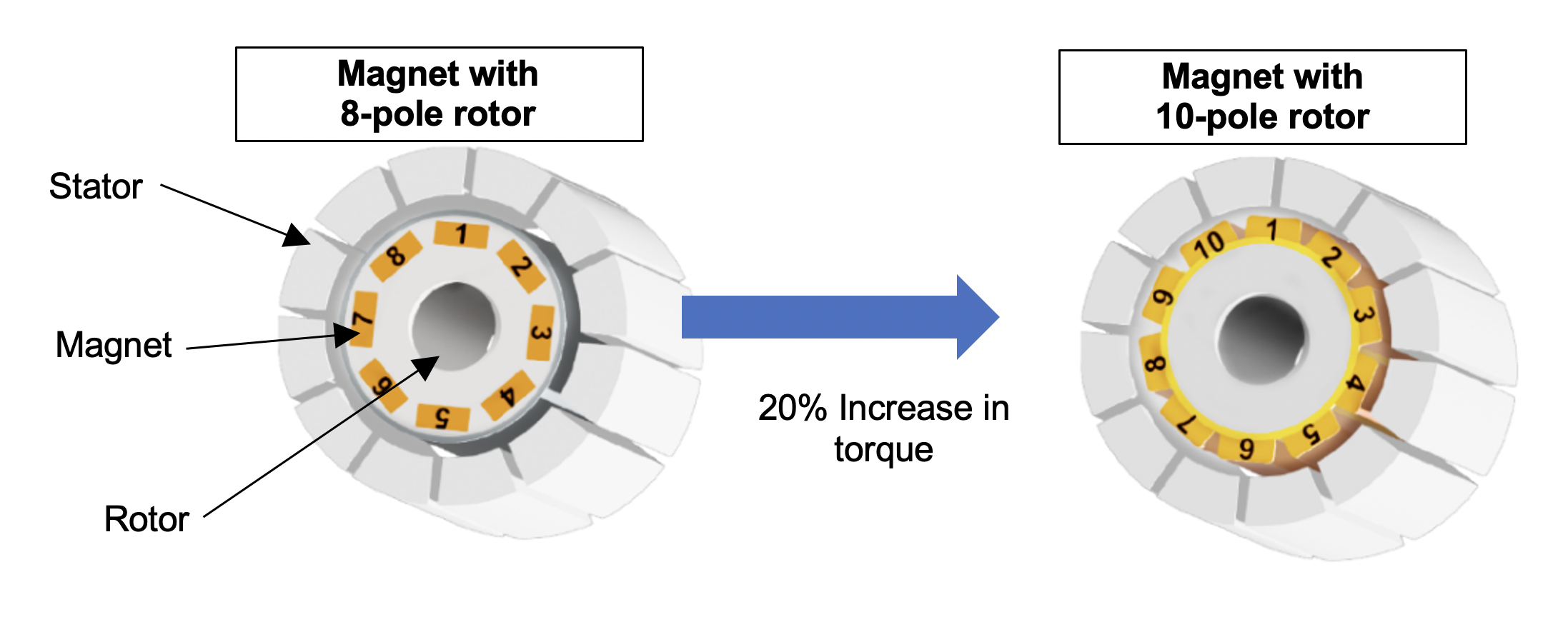

One of the improvements was an increase in the number of poles in the magnetic circuit, which improved the magnetic flux by revamping the core shape. Another critical change was the redesign of the magnets, which resulted in increased output of the motor performance without any increase in the size of the motor's outside diameter. Adopting anti-vibration material in the new rotor structure also resolved the potential issue of the rotor magnets cracking due to vibration.

According to feedback from the motor development engineers, the achievement resulted from meticulous brainstorming and critique of the conventional design. Increasing the motor output without any increase in size resulted in new issues, such as vibration and the risk of the magnets cracking. The engineers achieved the target performance output without increasing the motor's outside diameter by adding vibration-absorbing material and employing a low-vibration rotor core structure.

Improved magnetic flux, achieved by increasing the number of poles and redesigning the core and magnet shape

Vibration-absorbing material, low-vibration structure

Increased Output

The increased number of stator poles and optimized core shape delivered greater torque. Furthermore, the magnet shape was revamped for the improvement of magnetic flux.

Vibration Suppression

Using vibration-absorbing material and employing a low-vibration structure successfully achieved advanced results of vibration suppression.

Magnet Cracking Prevention

The magnet shape was changed to better align the outer rotor wall, which also increased torque and reduced vibration.

In conclusion, Panasonic's development of a compact motor for ergonomic strengthening of side-discharge outdoor units has significant implications for the industry. This achievement allows for a reduction in the number of motors used in an outdoor system while maintaining performance and a low profile. By decreasing the size and weight of the HVAC system, the new motor reduces the ergonomic workload on laborers, making the transportation of the units less laborious and exhausting. With a solid commitment to delivering products that benefit society, Panasonic will continue making waves in the tech industry for years.