Cutting Edge Solutions for ATE, IC Testers, Test and Measurement applications and more!

IC Testers/Test and Measurement Equipment Solutions

Automated Test Equipment (ATE) uses cutting edge automation technology to quickly measure and evaluate Integrated Circuits' test results. The unit undergoing testing is commonly known as Device Under Test (DUT). To make these systems more efficient and test complex circuits in a production environment, they need to be very fast, have clean signal switching, excellent temperature control, and make good thermal contact. Panasonic meets these challenges by offering various solutions that include our PhotoMOS® Solid-State Relays, Thermal Interface Materials, etc.

Featured Components & Devices for IC Testers

EVP-BB Series Tactile Switches

The EVP‑BB Series Tactile Switches combine a compact 2.6 × 1.6 × 0.53 mm footprint with IP67 protection and a robust laser‑welded construction that preserves a crisp, consistent tactile response while preventing actuator peel‑off under side‑load or impact. Their long operating life, enhanced actuator protection, and proven mechanical durability make them a reliable, space‑efficient choice for human-machine interface systems and demanding factory automation environments.

EVP-BL Tactile Switches

Panasonic’s EVP‑BL Series top‑push, 4‑terminal surface‑mount switch measures 2.8 mm × 1.9 mm and is available in 0.53 mm, 0.57 mm, and 0.60 mm height options. Its very short 0.15 mm travel enables fast, precise tactile operation, while a laser‑welded film structure provides IP67 protection against water, dust, oil, and other contaminants without sacrificing tactile feel. With its durable construction, crisp actuation, and low‑profile design, the EVP‑BL Series is well‑suited for human‑machine interface equipment and demanding factory automation environments where reliability and compact performance are essential.

PhotoMOS® CC Series Relays

The PhotoMOS CC Series is a sub-miniature solid-state relay technology now available in 60V, 40V and 100V options. The internal switching mechanism contains an oscillation circuit as well as a built-in Capacitor-Coupled Isolation driver IC. This differs from traditional PhotoMOS products which use an optical coupled isolation. The PhotoMOS CC Series is suitable for IC tester, probe card and board tester applications.

Photovoltaic MOSFET High Power Driver

The Photovoltaic MOSFET High Power Driver is available in a small package size (SSOP) with higher short circuit current and drop-out voltage to MOSFET’s gate. Capable of driving high Vgs MOSFET such as SiC MOSFETs this Driver is capable of high switching capacities at high switching speeds. Some common applications for Panasonic PhotoMOS Relays would be in the measurement market, security equipment, fire prevention systems and industrial machines.

RJ Series High Frequency Signal Relays

RJ Series Relays are high frequency Signal Relays with a Double Pole Double Throw (2 Form C) contact arrangement with 50 Ohm Impedance matching and can switch up to 8GHz transmission signal. In measurement equipment such as oscilloscopes and spectrum analyzers, these Relays are able to control high frequency signals for transmitting and receiving circuits as well as fulfilling the long life requirements of these devices. These Relays are ideal for use in a variety of applications including oscilloscopes, spectrum analyzers, and more.

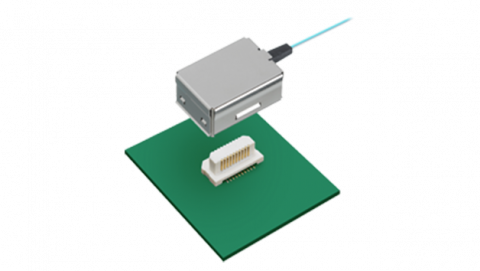

Active Optical Connectors

The Bi-Directional 1-Channel Type V Series Active Optical Connector is able to reverse the dual core optical fiber transfer in each direction simultaneously which makes it ideal for applications where mutual high speed transfer is needed between connected PC boards up to 8 Gbps. The Active Optical Connectors are ideal for measuring equipment, processing instruments applications, oscilloscopes, data transmission between test head mainframe, and more.

P4S Series Shield Type (0.4mm Pitch) Connectors

The P4S Series (0.4mm Pitch) Series Shield Type Narrow (Fine) Pitch Connectors are designed with Tough Contact construction to provide excellent vibration resistance and are compliant with all high-speed transfer standards. Pattern wiring to the connector bottom is made possible with a molded covering on the undersurface of the connector, offering greater flexibility in connector placement. The P4S Series is ideal for high speed data transmission applications, and more.

Y5BH Series (0.5mm Pitch) Connectors

The Y5BH Series Connectors are impedance matching Connectors that can accept both FPC and FFC with a 0.5mm pitch. The differential impedance matching is compatible with both 85 Ohms and 90 Ohms for various transmission standards such as the USB 3.1 Gen. 2 high-speed transmission standard (Transmission speed: up to 10 Gbps). With top and bottom contact construction and no pin assignments, the Y5BH Series contribute to optimal design freedom. The Y5BH Series is suitable for high speed data transmission applications, and more.

EVQ-Q2 Series Tactile Switches

6mm Square Thin Type SMD Tactile Switches are 6.5mm x 6.0mm and feature high durability and excellent tactile characteristics for click feeling, click sound, and travel. Providing short switch travel distance provides quick output and are available with or without ground terminals as well as J-Bent and straight terminal options. These Switches are ideal for use in a variety of applications including user interface for measuring equipment, medical devices, industrial lighting, industrial communications, and more.

ERA-3A Series

Panasonic, a world leader in Resistive Products, is pleased to announce the expansion of the ERA-3A Series of Thin Film Chip Resistors, High Reliability Type. These industry leading thin-film Resistors have been expanded to include new offerings in 10ppm 0.05% in the 0603 case size. Features include high reliability as well as high accuracy, low current noise, and excellent linearity. AEC-Q200 applicable, these Resistors are usable within demanding automotive applications.

EEF-GX Series SP-CAP™ Capacitors

The EEF-GX Series SP-CAP™ Specialty Polymer Aluminum Capacitors offer very low ESR while providing stable capacitance at higher frequencies and temperatures. The EEF-GX Series are also reliable alternatives to tantalum capacitors. These Capacitors operate at -55˚C to +105˚C and offer a capacitance range from 330μF to 470μF. The EEF-GX Series is RoHS compliant and halogen-free. The EEF-GX Series is suitable for mainboard applications.

EEU-FS Series Capacitors

The EEU-FS Series Aluminum Electrolytic Capacitors feature extremely high capacitance, long life, and low ESR—all wrapped in significantly smaller case sizes. The FS Series provides space reduction and allows for a reduced number of Capacitors on the board. Low ESR and high ripple current in the FS Series combines to provide a more stable, long-life Capacitor option. The EEU-FS Series is suitable for mainboard applications.

High Stability & Reliability Thin Film Resistors

Panasonic's ERA-xV and ERA-xK Series Thin Film Chip Resistors feature a soft terminal and passivated layer. With a total of 2,889 part number variants, Panasonic ERA-xV and ERA-xK Series Resistors provide design engineers with a wide array of Resistors to choose from specifically developed to handle extremely hazardous and challenging application environments. The ERA-xV and ERA-xK Series are suitable for amplifier circuit applications.

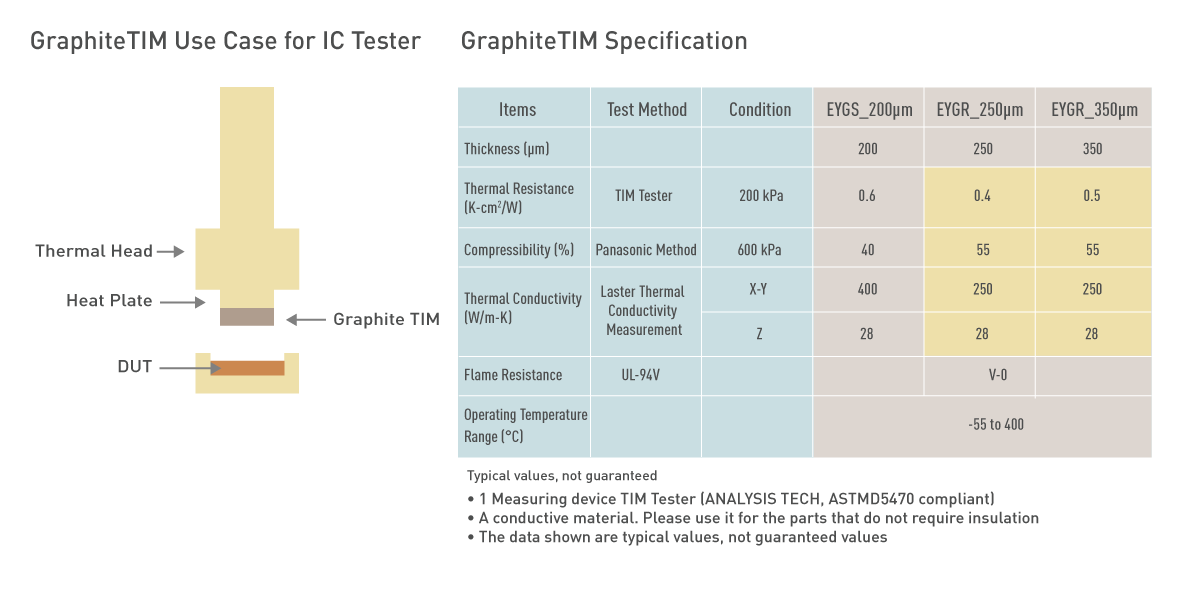

EYG-R & EYG-S Graphite TIM Soft-PGS

Panasonic's GraphiteTIM Soft-PGS is a graphite sheet that is dedicated to use as a thermal interface material. The Soft-PGS has very high compressibility compared to standard PGS, which enables reducing the thermal resistance by following the gap, warpage, and distortion of targets/substrates. Excellent heat resistance and reliability of the Soft-PGS help to obtain long service life and higher performance of various components, such as power modules. The EYG-R and EYG-S Series is suitable for heat plate applications.

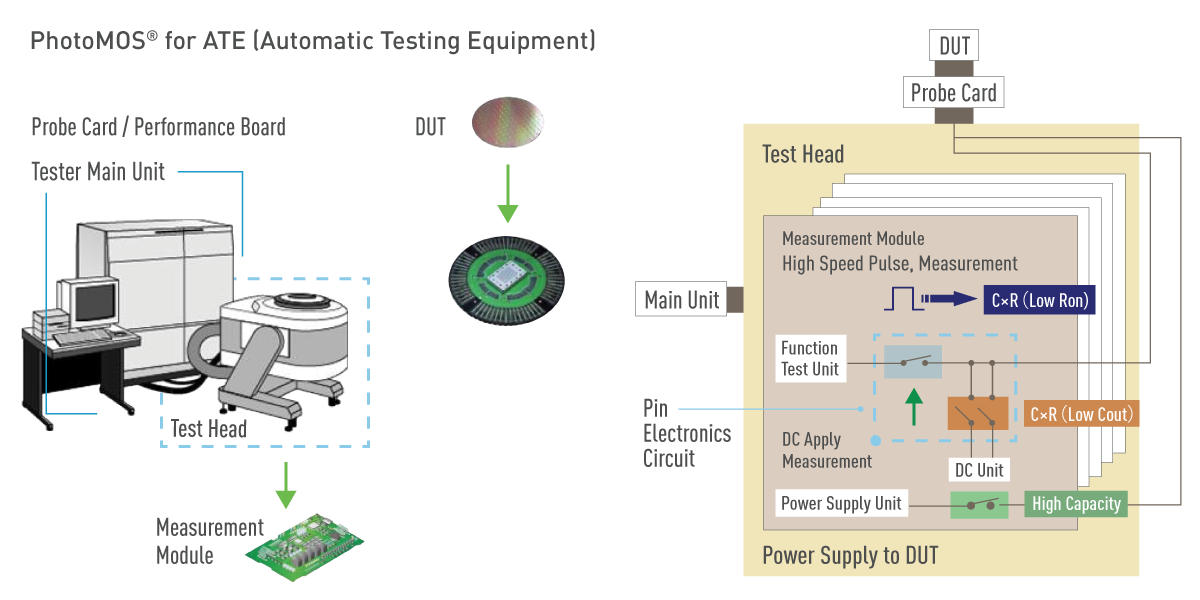

Automatic Testing Equipment Use Case Example for PhotoMOS® Relays

PhotoMOS® Relays strengthen and help secure measurement in semiconductor automatic test equipment (ATE) testing application. These devices are used to test semiconductor chips during manufacturing. PhotoMOS® is commonly used in this type of equipment to control the high-speed pulse and for the measurement signal inside the tester head. PhotoMOS® are suitable for these applications as they can control very low-level signals as well as high current signals while maintaining small leakage current and low noise properties. For use in the Functional Test Unit, which transmits a high-speed pulse, we recommend our Low On-Resistance PhotoMOS® to minimize losses. Next, we have the DC unit in which the measurements are being taken. For this, we recommend our Low output capacitance types for more accurate measurements. Lastly, there is the DC power supply unit, in which we recommend our higher capacity PhotoMOS® capable of switching larger loads required for the power supply unit.

Relay Solutions for Test Line Applications

RF Type SSOP Relays

Panasonic's PhotoMOS® RF Type SSOP 1 Form A Relays are characterized by their high performance and are adequate for small footprint equipment. These devices are equipped with low capacitance and on-resistance coupled with their miniature SSOP package size. These Relays are ideal for measuring equipment such as IC, ATE equipment, semiconductor performance boards, and function testers.

CxR Low Ron Relays:

PhotoMOS RF SSOP 1 FORM A CXR10

CxR Low Cout Relays:

RF Type VSSOP Relays

Panasonic's PhotoMOS® RF VSSOP 1 Form A Relays are characterized by their high performance and are adequate for small footprint equipment. Available in 30V and 40V with RF VSSOP 1 Form A arrangement these Semiconductor Relays are ideal for measuring and testing equipment. These devices are equipped with low capacitance and On-Resistance, which varies slightly at different load voltages coupled with its miniature VSSOP package size for space savings and high-density mounting.

CxR Low Ron Relays:

PhotoMOS RF VSSOP 1 FORM A CXR10

PhotoMOS RF VSSOP 1 FORM A CXR

CxR Low Cout Relays:

CC Type TSON Relays

The PhotoMOS® CC Series is a revolution in size and performance. The internal switching mechanism contains an oscillation circuit as well as a built-in Capacitor-Coupled Isolation driver IC. This differs from traditional PhotoMOS products which use an optically coupled isolation. By replacing the LED circuit, the package size can be substantially decreased, while also lowering power consumption.

Features:

- Sub-Miniature TSON Package (0.8 x 1.95 x 1.8mm)

- Low Current Consumption of 0.2A Max.

- High Temp Performance, Guaranteed to 105C

- Voltage-Driven Input Circuit

- RoHS/REACH Compliant

CxR Low Ron and Low Cout Relays:

Other PhotoMOS® Relay Solutions

Panasonic HF SSOP 1 Form A High Capacity PhotoMOS® Semiconductor Relays are equipped in a miniature SSOP package for high-density mounting and are rated at 600V and 150mA. The HF SSOP Relays are suitable for applications ranging from test and measurement equipment to industrial applications. These PhotoMOS® Semiconductors Relays feature low on-resistance of 8 Ohms, high-speed operation, and an isolation voltage of 1500Vrms.

Learn how to increase reliability by changing Reed Relays to PhotoMOS. Reed Relays, including Mercury Reed Relays, dominated the market until the introduction of Solid-State devices. In the tester market, there is a growing trend to replace Reed Relays with PhotoMOS Relay solutions to increase long-term performance and reliability. Solid State Relays excel in reliability; the absence of physical contact to provide isolation of the electrical signal causes leakage current. Panasonic's "T-circuit" design significantly reduces leakage current. A solution that uses three separate PhotoMOS Relays to create a circuit optimized for reducing leakage current and maximizing isolation at a high frequency.

Panasonic PhotoMOS® Relays are MOSFET-enabled Solid State Relays featuring low off-state leakage current and stable on-resistance over the component lifetime. Low CxR values, high optical isolation between input and output, and DC and AC / DC load ratings. MOSFET drivers are available in SSOP, SOP 4-pin, and DIP 6-pin.

IC Test Use Case Example for Thermal Management Solution

Features:

- Thermal Resistance: 0.2Kcm²/W (600 kPa)

- A Close Adherence Would Make the Product Fit Into the Uneven Part and Enhance Performance

- Thermal Conductivity: X-Y Direction 400W/mK, Z Direction (30W/mK)

- Compressibility: 40 % (600k Pa)

- High and Long Term Reliability: Operating Temperature Range –55 to 400 °C

- RoHS Compliant

Benefits:

- Custom Cut Footprints For IGBT Modules From Major IGBT Manufacturers

- Available In Standard Sized Sheets

- Increased Heat Transfer Due To Better Fitting On Uneven Surfaces

- Simple Procedure For Installation

- Reduction In Labor Costs Due To Easy Installation

- No Deformation Over Time

- Low Maintenance

- Increases The Lifetime and Reliability Of The IGBT Module

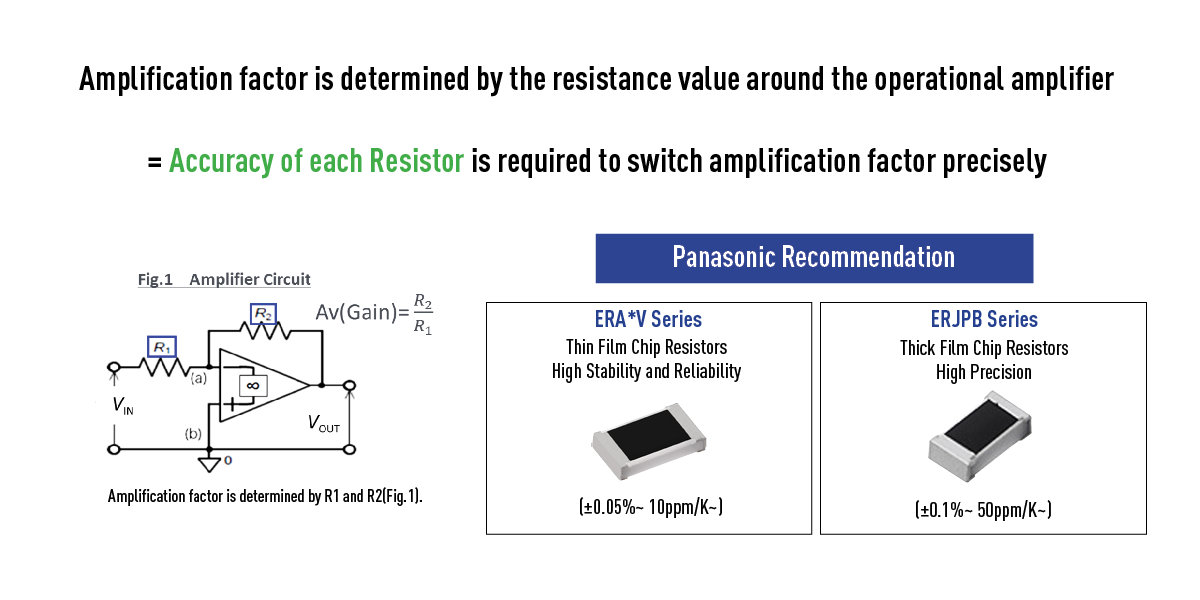

Tester/IC Testers Use Case Example for High Precision Resistors

The ERA-xV and ERA-xK Series Resistors provide design engineers with a wide array of Resistors to choose from specifically developed to handle extremely hazardous and challenging application environments. The AEC-Q200 qualification of the ERA-xV and ERA-xK Series ensures that these Resistors are meeting the most stringent quality standards in the industry. These parts have met the requirements for AEC-Q200 HBM electrostatic discharge test (AEC-Q200-002 HBM Level 1c and above) making them durable to ESD events.

The ERJ-PB Series Resistors are best for applications requiring a high precision Resistor with higher power. The ERJ-PB Series Thick Film Resistors achieve the tolerance ±0.1% because of a highly reliability metal glaze. The ERJ-PB Series offer a broad range of part numbers for easy replacement from existing sources. AEC-Q200 Compliance ensures strict quality control standards are being enforced.