Solutions for ICT Edge Computing and Base Station Servers

Published on- Capacitors

- Resistors

- Electronic Materials

As 5G, the fifth generation of wireless technology and beyond, drives the need for high-speed, low-latency communication, base stations have become central to modern ICT infrastructure, relying on edge computing architectures that include RRHs, RUs, DUs, CUs, edge servers, and thermal management systems. Design engineers must select components and materials that are compact, heat-resistant, reliable, and low in transmission loss, all while supporting scalability and efficiency. Panasonic Industry offers advanced product solutions that provide a reliable, precise technological foundation, essential for building a high-speed, low-latency communication infrastructure with confidence.

Base Station Servers: The Backbone of Edge‑Driven Networks

As the demand for high-speed data transmission and ultra-low-latency communication grows with the rollout of the fifth generation of wireless cellular technology (5G) and beyond, base stations have become the backbone of modern Information and Communication Technology (ICT) infrastructure. These systems rely heavily on edge computing architectures that include components such as remote radio heads (RRHs), radio units (RUs), distributed units (DUs), central units (CUs), edge servers, and thermal management systems. Design engineers face the challenge of selecting components and materials that combine compactness, heat resistance, high reliability, and low transmission loss, while ensuring scalability and efficiency.

Panasonic Industry provides a robust portfolio of electronic components and materials specifically engineered to meet these challenges. From polymer capacitors and resistors to high-performance circuit board materials, thermal interface materials, and transparent conductive films, Panasonic delivers the technological foundation needed to build next-generation base station solutions with confidence and precision.

ICT Solutions Diagram

Base stations today are more than just signal transmitters; they are compact, high-performance computing environments designed to handle large volumes of data locally. As edge computing becomes a vital enabler of fast, localized data processing, system designers require components that minimize power loss, dissipate heat efficiently, and maintain signal integrity over high frequencies and long operating cycles. The use of distributed edge computing architecture (splitting computing between DUs, CUs, and edge servers) places further demands on power and signal chain components.

Panasonic Industry meets this demand with a wide range of passive components and advanced materials designed for ICT applications. These products are engineered for high reliability, space efficiency, and long-term durability even in the most challenging environmental conditions.

Polymer Capacitors for 48V Power Supply Architectures

48V architectures increasingly power modern base stations to enhance power efficiency and reduce distribution losses. This shift requires capacitors that can handle high voltage, high ripple currents, and high-temperature reflow processes while maintaining long lifespans. Panasonic’s polymer capacitor lineup is uniquely suited for these requirements:

- SP-Cap™ (Conductive Polymer Aluminum Electrolytic Capacitors): These capacitors offer extremely low ESR values and are available in high-voltage configurations. Their compact size and robust reflow resistance make them ideal for space-constrained power supply units in base stations.

- POSCAP™ (Tantalum-Polymer Capacitors): Known for stable capacitance across high frequencies, low-voltage configurations, and high temperatures, POSCAP capacitors are especially effective in applications involving fluctuating loads or variable processing demands, such as power management ICs and FPGA-based compute modules.

- OS-CON™ Capacitors: With low ESR, high ripple-current tolerance, and exceptional noise-suppression capabilities, OS-CON capacitors are critical for maintaining clean, stable power delivery in densely populated PCBs.

- Polymer Hybrid Capacitors: Combining the benefits of electrolytic and solid-polymer capacitor technologies, these components deliver the best of both worlds: excellent ripple-current tolerance, high endurance, and longer service life across wide temperature ranges.

Across all series, Panasonic offers options with voltage ratings above 50V, making them well-suited for next-generation 48V power supply designs in base stations and edge servers.

High-Performance Resistors for Harsh ICT Equipment

Precision, stability, and environmental resistance are critical when managing signal paths (Amplifier), voltage dividers, and current sensing circuits in ICT equipment. Panasonic’s resistors offer both performance and durability to meet the diverse needs of edge computing hardware.

- ERA Series Thin Film Chip Resistors: These resistors offer high precision with tight tolerance and low TCR (temperature coefficient of resistance). Their robust construction supports high-reliability applications where signal accuracy and stability are paramount. ERA resistors are ideal for analog front ends, precision voltage feedback, and noise-sensitive control circuits.

- ERJ-* Series Anti-Sulfurated Thick Film Resistors: Designed to withstand harsh environmental conditions, these resistors maintain electrical stability even when exposed to sulfur, humidity, and dust. This is particularly important in remote and outdoor base station installations, where environmental exposure can compromise unprotected components.

Incorporating these resistors into base station designs enhances reliability and ensures consistent operation under real-world conditions.

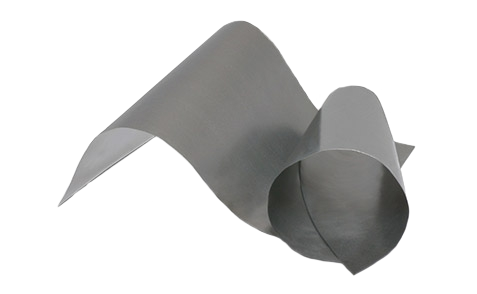

FineX Transparent Conductive Film

FineX (Fine Cross) represents Panasonic’s innovative solution for engineers seeking flexible, transparent conductive materials that don't compromise performance. Developed using a proprietary roll-to-roll manufacturing method, FineX features a double-sided metal mesh wiring structure on a flexible substrate. This unique approach enables high conductivity with high optical transmittance.

Benefits of FineX include:

- High Transmissivity: Narrow wiring width allows light to pass through while maintaining strong conductive pathways.

- Low Electrical Resistance: High aspect ratio with narrow and deep wiring supports efficient current flow with minimal loss.

- Mechanical Flexibility: Enables applications in curved surfaces, enclosures, and tight mechanical designs.

- Design Adaptability: Easily customized to meet various shapes, sizes, and electrical requirements.

Applications include transparent antennas, transparent EMI shielding, transparent heaters, Head-up displays, and sensor panels embedded in base station enclosures. Its combination of aesthetic compatibility and electrical performance makes FineX a strong candidate for user-facing or integrated RF system elements.

MEGTRON Circuit Board Materials

For high-frequency edge computing and networking equipment, signal integrity and heat resistance are paramount. Panasonic’s MEGTRON series of multi-layer circuit board materials addresses both challenges with engineered laminates that offer:

- Low Transmission Loss: Essential for maintaining signal integrity in high-speed SerDes and communication channels.

- Excellent Thermal Performance: Enables high layer count circuit board fabrication and operation over a wide span of temperatures in the field.

- High Reliability: Proven track record in aerospace, and networking industries for long-term stability.

MEGTRON circuit board laminates are ideal for the high speed PCBs in DUs, CUs, and edge servers that manage demanding data-processing workloads.

Thermal Solutions for High-Density Systems

As edge computing hardware becomes more compact and power-dense, managing thermal energy is no longer optional; it’s essential. Panasonic offers a complete portfolio of thermal interface materials (TIMs) to meet the challenge:

- PGS Graphite Sheets: Deliver ultra-high in-plane thermal conductivity (up to 1950 W/m·K) and flexibility. These sheets spread heat evenly across surfaces to prevent hotspots.

- GraphiteTIM PGS: Reduce thermal resistance between chips and heatsinks or chassis. Their ability to conform to uneven surfaces improves mechanical contact and overall heat transfer.

These materials are especially valuable in space-constrained environments such as base station enclosures, where active cooling may be limited.

Application Spotlight: Building Base Stations for the Future

The comprehensive system provides a visual representation of how Panasonic components are deployed across base station infrastructure. From edge servers and RF front ends to power management and thermal systems, every subsystem is enhanced by components designed for performance and reliability:

- Distributed and Central Units (DU/CU): by Megtron PCB laminates, polymer capacitors, and thin film resistors for power integrity and signal clarity.

- Edge Servers: Combine polymer hybrid capacitors with advanced thermal interface materials to manage dense compute loads.

- Interface Panels and Sensor Layers: Leverage FineX for transparency, flexibility, and electromagnetic compatibility.

By prioritizing reliability, efficiency, and scalability, Panasonic enables developers to design ICT systems that are future-ready and optimized for power, performance, and longevity.

Conclusion

Edge computing and base station design are evolving rapidly, driven by the insatiable demand for real-time data access, lower latency, and more intelligent network architectures. Panasonic’s extensive component and materials portfolio, including polymer capacitors, thin and thick film resistors, FineX transparent conductive films, MEGTRON PCB laminates, and thermal interface materials, empowers engineers to meet these challenges head-on.

By prioritizing reliability, efficiency, and scalability, Panasonic enables developers to design ICT systems that are not only future-ready but also optimized for power, performance, and longevity. Whether you're building edge computing modules, optimizing thermal designs, or ensuring stable power conversion at 48V, Panasonic provides the tools to succeed.

Loading form